In the world of manufacturing, molds play a crucial role, ensuring products are produced efficiently and with precision. Medical test tube molds and toy racket molds serve as essential tools in their respective industries, fulfilling high-quality production demands. In the medical field, test tube molds are critical for producing the vast quantities of medical test tubes needed by hospitals and labs. Meanwhile, in the toy industry, toy racket molds enable manufacturers to swiftly create various styles of rackets, meeting the ever-growing demand in the toy market. This article delves into how these molds contribute to efficient production and quality assurance in both fields.

Medical Test Tube Mold: Supporting Quality and Efficiency in Healthcare

Medical test tube molds are indispensable in the healthcare manufacturing sector. The precision and durability of these molds ensure that each test tube produced meets strict medical standards, providing a safe and reliable tool for collecting and analyzing samples. For hospitals and labs, medical test tubes are an essential part of everyday operations, used in testing blood, urine, and other samples critical for diagnosis.

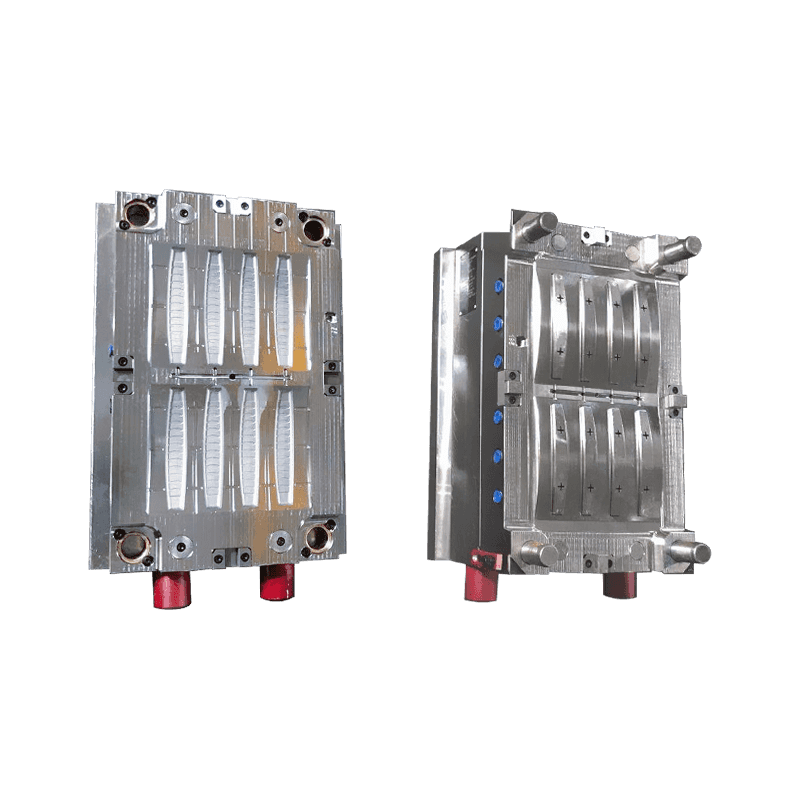

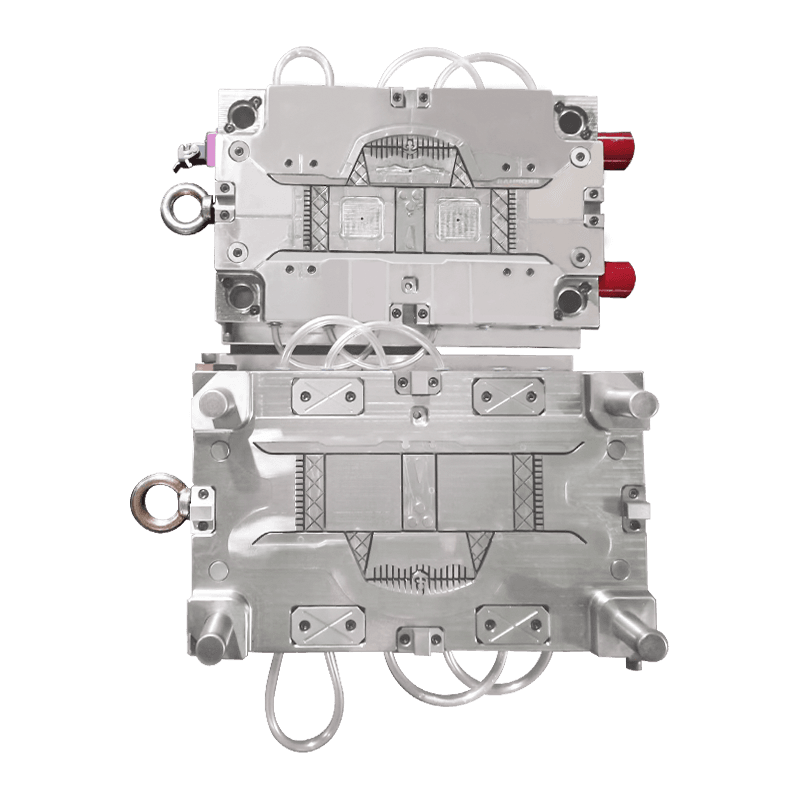

Medical Test Tube Mold

A quality medical test tube mold is designed with high-grade materials that can withstand constant use without degrading, enabling the mass production of test tubes with consistent quality. These molds undergo rigorous testing to ensure they meet medical-grade standards. As a result, each test tube produced is uniform in size, shape, and material quality, guaranteeing its suitability for delicate medical procedures. For instance, a major healthcare supplier utilized specialized test tube molds to meet a surge in demand during a flu outbreak, providing essential equipment that met safety and reliability standards in record time.

In terms of production efficiency, a single medical test tube mold can produce thousands of units in a short period, making it a highly efficient tool. This capability is essential for large-scale healthcare providers and distributors who need to keep up with the continuous demand for medical supplies. By maintaining a steady flow of high-quality test tubes, medical test tube molds support the ongoing efforts of healthcare professionals and researchers in their critical work.

Toy Racket Mold: Bringing Fun to the Toy Industry

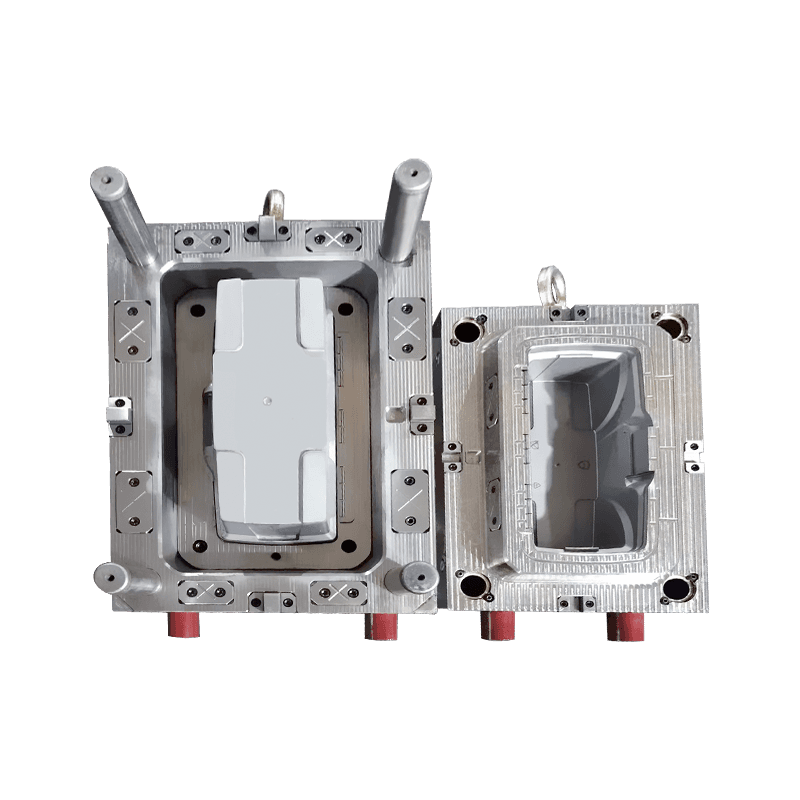

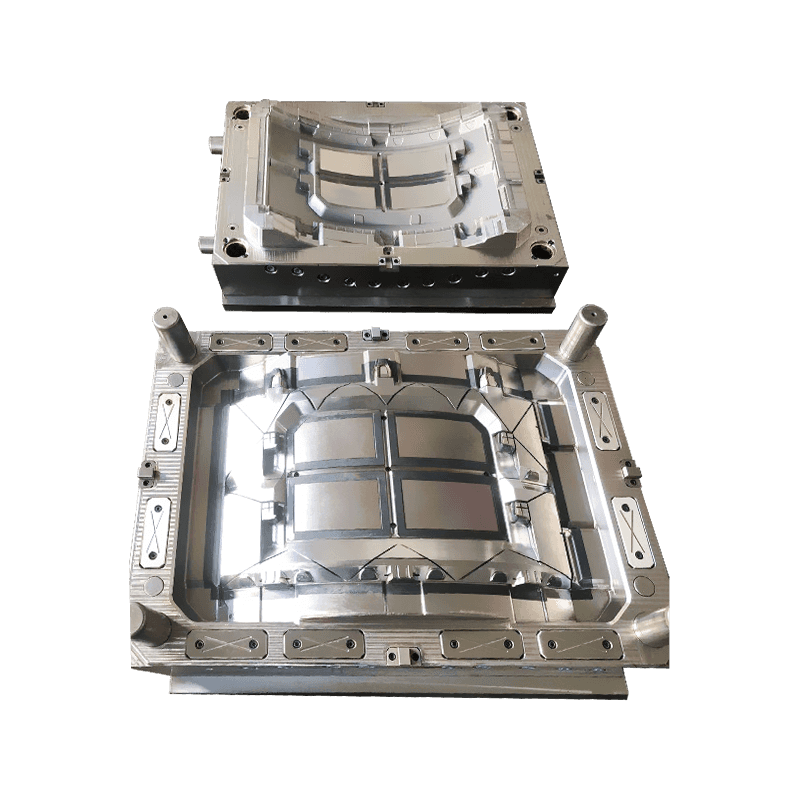

On the other end of the manufacturing spectrum, toy racket molds are integral to the toy industry, where speed and variety are key. These molds allow manufacturers to create multiple styles of toy rackets, from beginner designs for toddlers to more advanced models for older children. With toy racket molds, producers can introduce a variety of racket shapes, colors, and sizes to keep up with consumer preferences.

A well-designed toy racket mold is made with high-quality steel or aluminum to ensure durability and longevity. The molds must be capable of producing rackets that are safe for children, meeting toy industry safety standards. The use of reliable materials and precision molding techniques ensures that each toy racket is smooth, lightweight, and easy to handle, meeting the needs of young players and their parents.

In a large-scale toy factory, a single toy racket mold can produce thousands of units each day, enabling manufacturers to keep pace with the demands of retail chains and toy distributors. For example, a popular toy company used specialized toy racket molds to produce a summer line of rackets, ensuring they were ready to hit the shelves before the peak outdoor play season. The molds allowed for rapid production without sacrificing the quality or safety of the final products, helping the company fulfill large orders from major retailers.

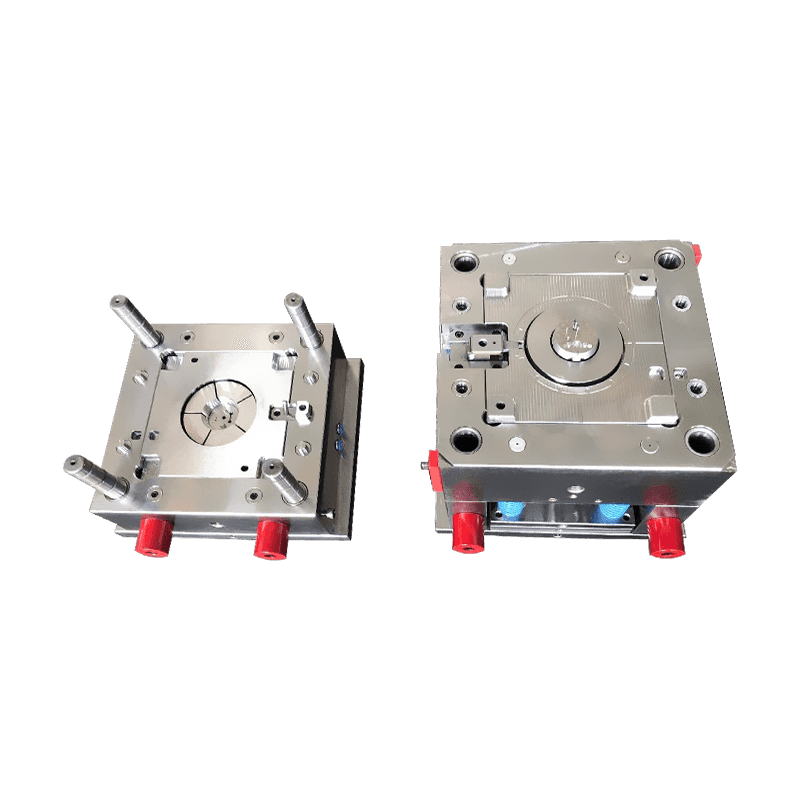

Key Features of Medical Test Tube Molds and Toy Racket Molds

Both medical test tube molds and toy racket molds are designed with features that enhance their performance and utility:

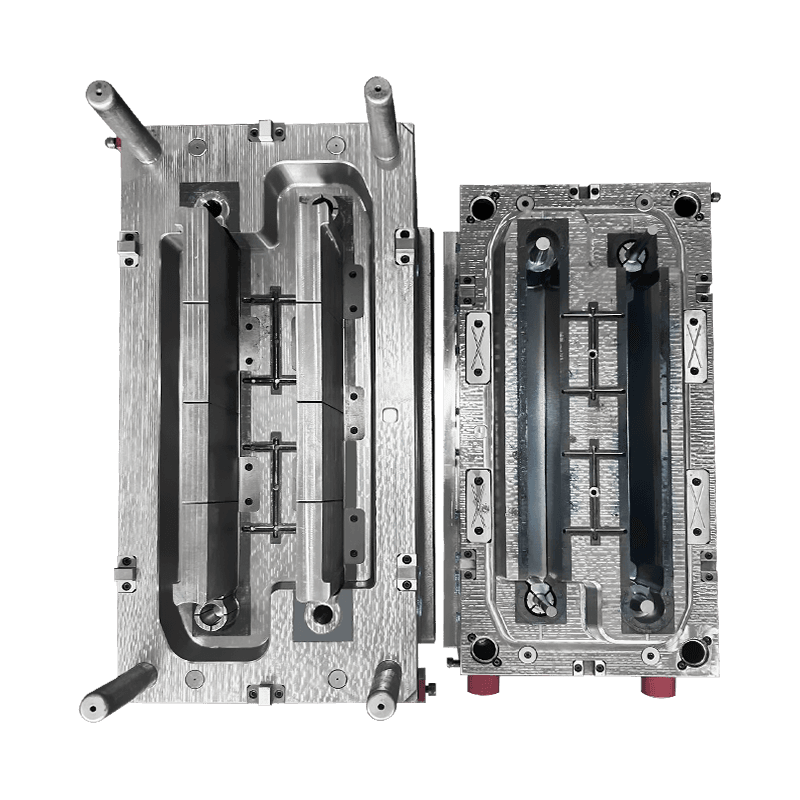

Durable Materials: These molds are crafted from high-grade metals, like stainless steel or aluminum, ensuring they can handle repetitive use without warping or breaking.

Precision Engineering: The detailed engineering of these molds guarantees that each unit produced meets exacting specifications, whether for medical use or play.

High Production Capacity: Both molds are designed to produce large quantities quickly, meeting the high demand in the healthcare and toy sectors.

Safety Compliance: In medical and toy production, safety is paramount. These molds are crafted to meet stringent safety standards, ensuring the final products are safe for use.

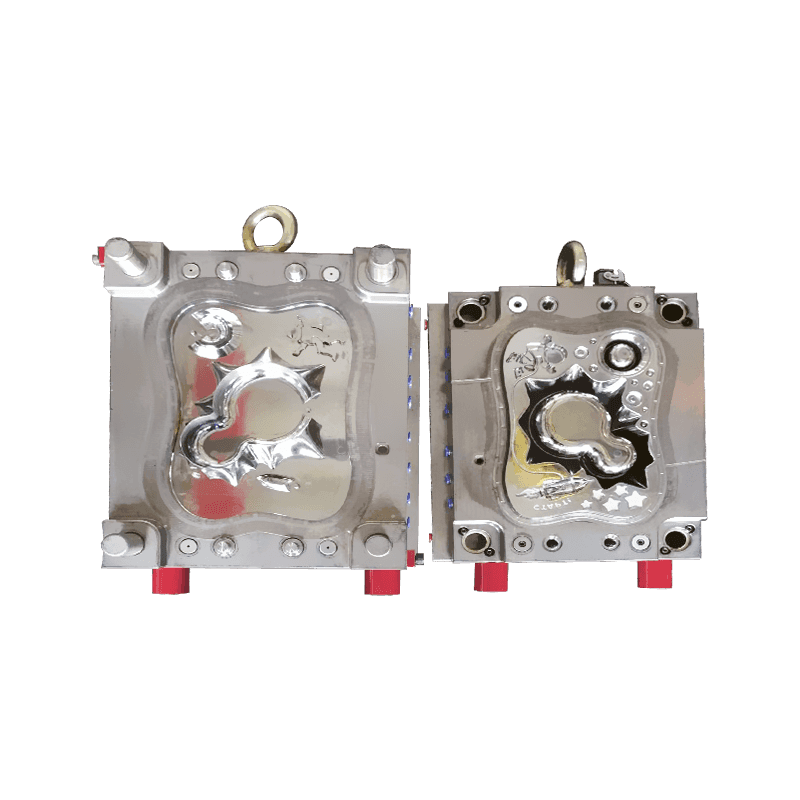

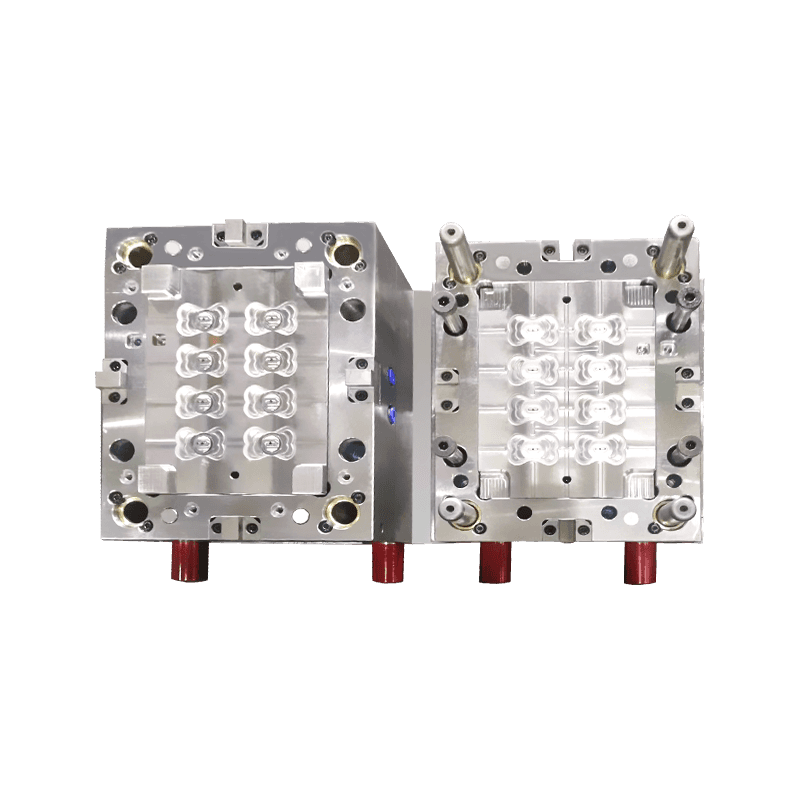

Choosing the Right Mold for Your Manufacturing Needs

When selecting a medical test tube mold or toy racket mold, it's essential to consider the material quality, production capacity, and compliance with industry standards. Consulting with experienced mold manufacturers ensures that companies receive a mold tailored to their specific requirements, optimizing production efficiency and product quality.

In addition, working with mold suppliers who understand the unique needs of each industry, such as medical-grade standards for test tubes or child safety standards for toys, can provide manufacturers with a competitive edge. With the right mold, manufacturers can achieve consistent quality, reduce waste, and meet demand effectively.

English

English 中文简体

中文简体 русский

русский

Contact Us