We are committed to providing customers with high-quality, precision mold solutions.

Toolbox Molds

Cat:Toolbox And Accessories Mold

Toolbox molds encompass a variety of types designed to produce different styles and sizes of toolbox...

See Details

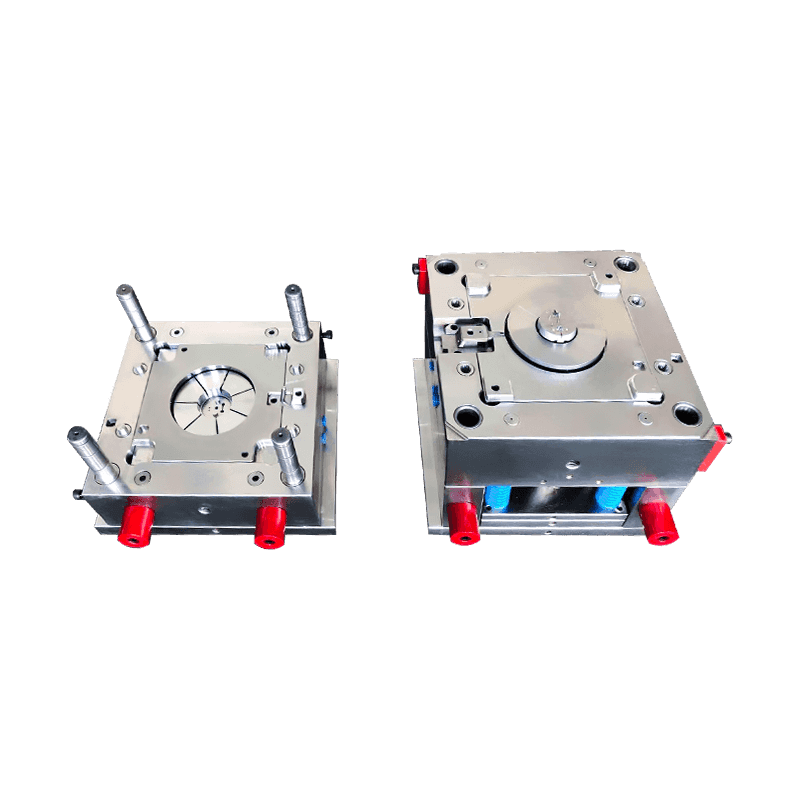

Ventilation Mold and Fan Mould Design for Airflow and Energy Efficiency in China

When it comes to ventilation and fan systems, the importance of mould design cannot be overstated. Whether for industrial, commercial, or residential use, the ventilation mold and fan mould are central to how efficiently these systems operate. The shape, size, and material of these moulds can significantly affect airflow dynamics, noise levels, and overall energy consumption. In this article, we explore the scientific principles behind the design of fan blades and ventilation units and how advanced moulding techniques play a crucial role in optimizing their performance.

The Role of Fan Moulds in Airflow Dynamics

The fundamental purpose of any fan is to move air efficiently. The design of the fan mould directly influences how well this task is accomplished. Airflow dynamics are primarily determined by the shape and size of the fan blades. For instance, larger fan blades with a curved design can move more air, while smaller blades might be more energy-efficient but move less air. The ventilation mold used to create these blades ensures that each component fits perfectly to optimize airflow while maintaining structural integrity.

Moulding techniques can create fans with blades that are designed to minimize turbulence and maximize air displacement. High-quality ventilation moulds are essential in producing blades with precise curvature and surface finishes that reduce air resistance, allowing for smoother airflow and better performance. In poorly designed moulds, irregularities or imperfections in the blade shape can cause to inefficient airflow and increased energy consumption.

The Impact of Shape and Size on Noise Levels

Fan noise is often a significant concern in many applications, especially in residential or office spaces where quiet operation is required. The design of the fan mould plays a crucial role in controlling noise levels. Fan blades that are poorly moulded can create vibrations that result in unwanted noise. A well-designed ventilation mold, however, ensures that the blades have a consistent and smooth shape, reducing turbulence and thus lowering noise.

The size of the fan also contributes to noise production. Larger fans tend to generate more noise, but when designed correctly, they can distribute airflow more evenly, reducing the high-pitched, annoying sounds produced by smaller, faster-moving fans. By adjusting the size and design of the fan mould, manufacturers can achieve the balance between airflow and noise reduction, making fans more suitable for quieter environments without compromising on performance.

Energy Efficiency: How Fan Moulds Affect Power Consumption

Energy efficiency is a key concern in fan and ventilation systems, particularly in industrial and commercial applications where long hours of operation can casue to high energy bills. The efficiency of these systems often hinges on the design of the ventilation mold and fan mould. Moulds that are designed with aerodynamics in mind help reduce drag, allowing the fan to use less power to achieve the desired airflow.

Blades created through advanced moulding techniques are often lighter and more durable, meaning they can operate at lower speeds while still moving the same amount of air. This not only saves on energy costs but also reduces wear and tear on the fan components. In turn, this extends the lifespan of the fan, making it a more cost-effective solution over time.

Precision in Moulding: The Key to Optimal Performance

To achieve the possible airflow, noise reduction, and energy efficiency, precise ventilation mould and fan mould designs are essential. Manufacturers use advanced moulding techniques like injection moulding, die-casting, and 3D printing to ensure that each component meets strict performance standards. With precision moulds, the exact shape and size of each part are carefully crafted to minimize imperfections and maximize efficiency.

Moreover, modern moulding techniques allow for the creation of complex designs that were once impossible. With the advent of new technologies, fan blades can now be designed with more intricate geometries that enhance airflow dynamics while also reducing energy consumption and noise.

The design of fan moulds and ventilation moulds is a science in itself. From airflow dynamics to energy efficiency and noise reduction, every element of the mould impacts the performance of the fan. Advances in moulding techniques and materials have enabled the creation of fans that are quieter, more efficient, and more durable than ever before. As technology continues to evolve, the science behind these moulds will only improve, making fans and ventilation systems more effective and energy-efficient, helping both consumers and industries optimize their operations.

Contact Us