We are committed to providing customers with high-quality, precision mold solutions.

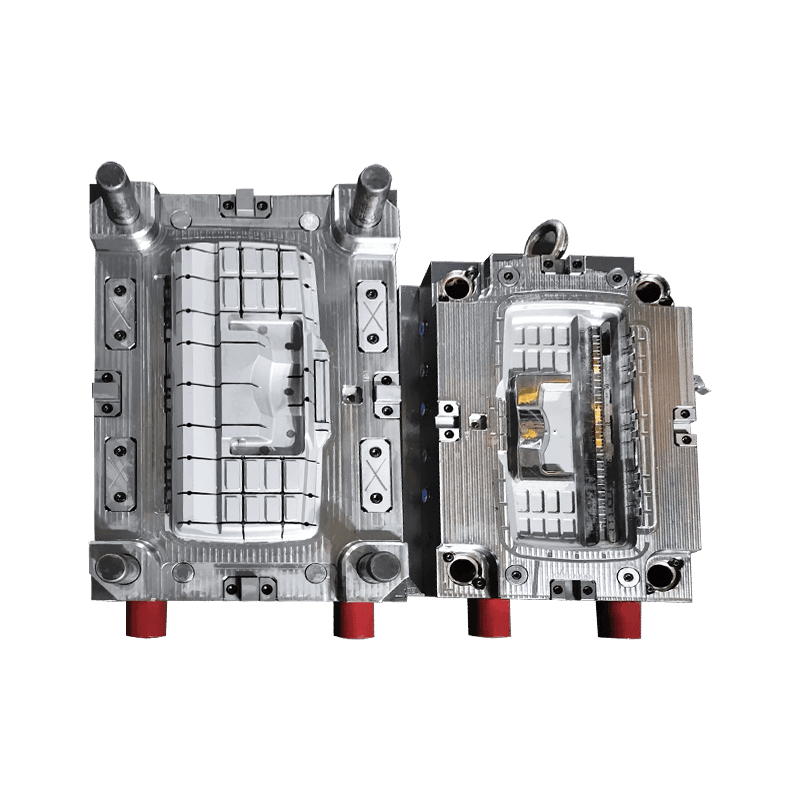

Toolbox Molds

Cat:Toolbox And Accessories Mold

Toolbox molds encompass a variety of types designed to produce different styles and sizes of toolbox...

See Details

Toolbox handles are an integral part of any toolbox, providing users with a comfortable grip and a secure hold. The molds used to create these handles, known as toolbox handle molds, are designed with a keen focus on functionality, precision, and durability.

Ergonomic Design

One of the primary features of toolbox handle molds is their ergonomic design. These molds are crafted to produce handles that fit comfortably in the user's hand, reducing strain and fatigue during use. The contours and curves of the mold are carefully designed to accommodate the natural shape of the human hand, ensuring a secure grip.

Material Compatibility

Toolbox handle molds are made from materials that can withstand the rigors of the injection molding process. High-quality steel is often used due to its strength, durability, and heat resistance. This material choice ensures that the molds can produce a consistent number of handles without significant wear or deformation.

Precision Engineering

Precision is a hallmark of high-quality toolbox handle molds. These molds are engineered to exacting standards, ensuring that each handle produced is uniform in size, shape, and fit. The use of advanced CAD/CAM software and CNC machining techniques allows for the creation of molds with intricate details and tight tolerances.

Durability and Longevity

The durability of toolbox handle molds is crucial for cost-effective manufacturing. A mold that can withstand numerous production cycles without the need for frequent maintenance or replacement is highly desirable. The materials and construction methods used in the creation of these molds are chosen to their lifespan.

Customizability

Another notable feature of toolbox handle molds is their customizability. Manufacturers can tailor the design of the mold to meet specific customer requirements, including the addition of logos, unique textures, or specialized grip patterns. This flexibility allows for the production of handles that are not only functional but also visually appealing and brand-specific.

Environmental Considerations

In today's environmentally conscious market, the features of toolbox handle molds also extend to their environmental impact. Molds are designed to produce handles from materials that are recyclable or made from recycled content, aligning with the industry's move towards sustainability.

Die Cast Mold Manufacturers: The Artisans of Precision

Die cast mold manufacturers are the unsung heroes of the manufacturing world, creating the intricate molds that give life to a wide range of products, including toolbox handles. These manufacturers possess a unique set of skills and expertise that are essential for the production of high-quality molds.

Expertise in Material Selection

Die cast mold manufacturers have a deep understanding of the materials suited for die casting. They select materials that offer the right balance of strength, durability, and heat resistance, ensuring that the molds can withstand the high pressures and temperatures involved in the die casting process.

Technology

These manufacturers invest in technology, including advanced CNC machines, 3D printers, and CAD/CAM software. This technology allows them to create molds with exceptional precision and detail, meeting the exacting requirements of their clients.

Quality Assurance

Quality assurance is a cornerstone of die cast mold manufacturing. Manufacturers implement rigorous quality control measures at every stage of the production process, from the design and machining of the mold to the final inspection of the finished product. This commitment to quality ensures that the molds produced are reliable and consistent.

Customization and Innovation

Die cast mold manufacturers are not just producers; they are also innovators. They work closely with clients to understand their unique needs and develop customized solutions. This collaborative approach fosters innovation and allows manufacturers to push the boundaries of what is possible in mold design and production.

Contact Us