The art of die casting has been a cornerstone of manufacturing for decades, offering a precise and efficient method for producing complex parts with a high degree of accuracy. Among the various applications of die casting, the creation of fruit basket molds stands out for its practicality and versatility.

At the heart of the die casting process is the mold factory, a place where innovation and precision meet to create functional and aesthetically pleasing products. The Fruit Basket Die Casting Mold Factory is a prime example of such a facility, where skilled craftsmen and technology come together to produce high-quality molds for fruit baskets.

Precision and Quality

The practicality of fruit basket die casting molds begins with the precision and quality of the molds themselves. The Fruit Basket Die Casting Mold Factory ensures that each mold is crafted to exacting standards, allowing for the production of fruit baskets with consistent dimensions and a smooth finish.

Material Selection

The selection of materials is another aspect where the Fruit Basket Die Casting Mold Factory excels. By choosing the right materials for the molds, the factory ensures that the resulting fruit baskets are durable, lightweight, and resistant to wear and tear.

Design Flexibility

The practicality of fruit basket die casting molds is further enhanced by the design flexibility they offer. The Fruit Basket Die Casting Mold Factory can create molds for a wide range of fruit basket designs, from simple and functional to intricate and decorative.

The Manufacturing Process

The manufacturing process at the Fruit Basket Die Casting Mold Factory is a testament to the practicality of die casting molds. The process involves several stages, each carefully controlled to ensure the quality output.

Design and Engineering

The step in the process is the design and engineering of the mold. The Fruit Basket Die Casting Mold Factory's team of engineers uses advanced computer-aided design (CAD) software to create detailed blueprints of the mold, taking into account the desired shape, size, and features of the fruit basket.

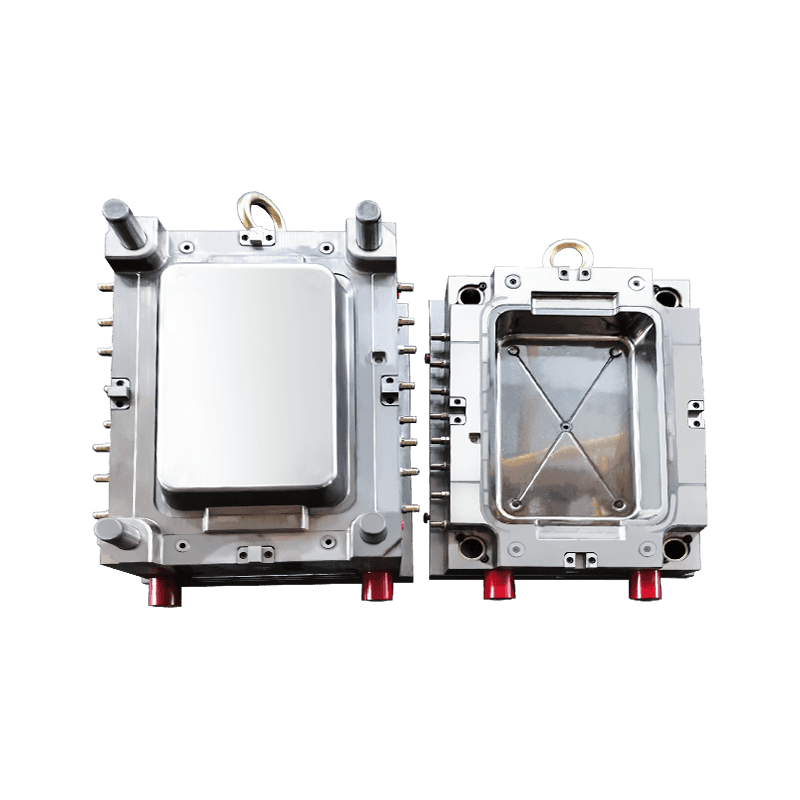

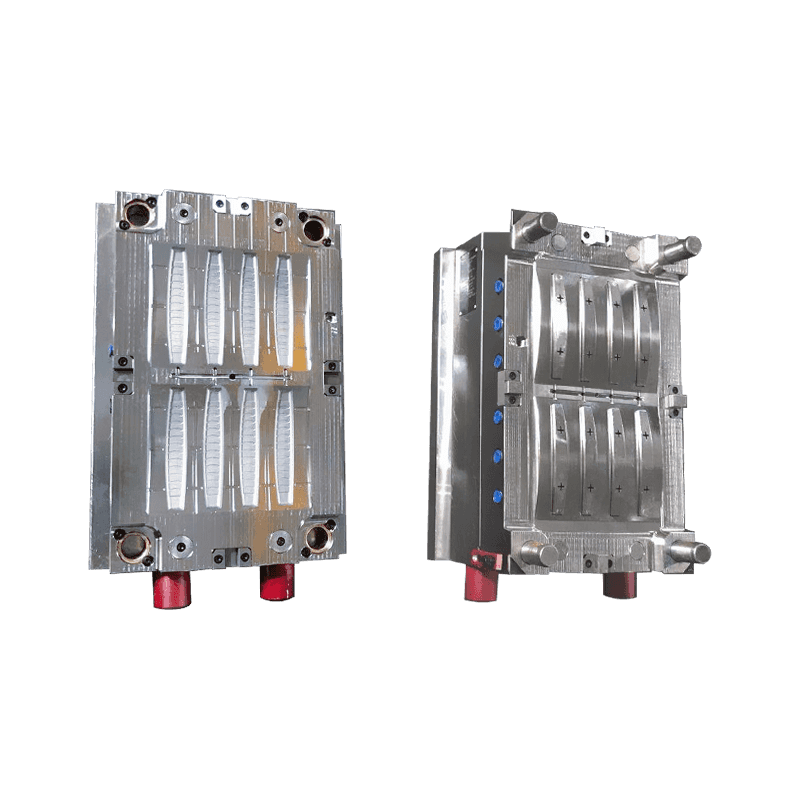

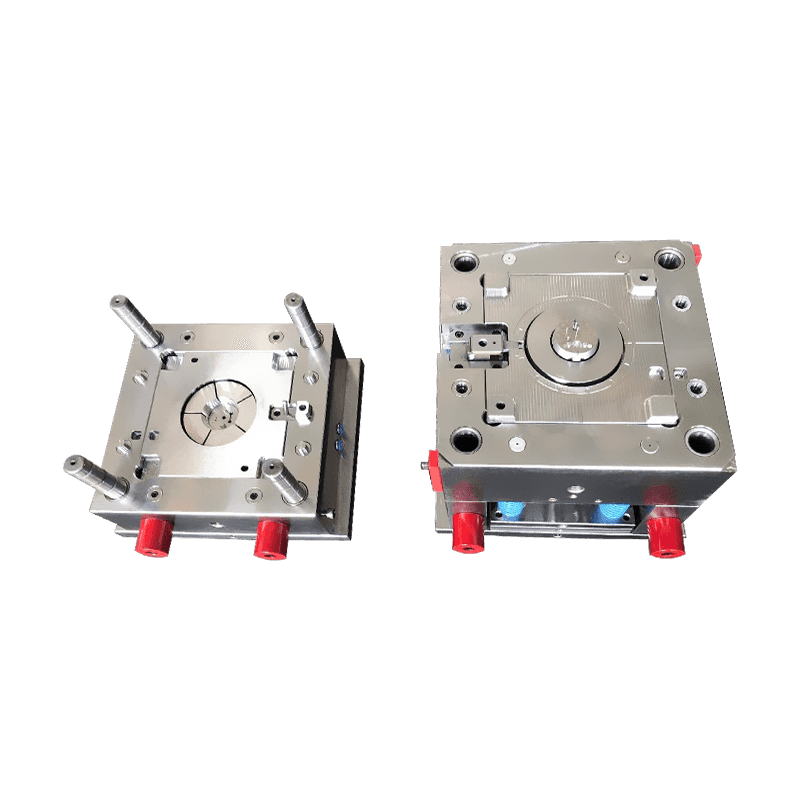

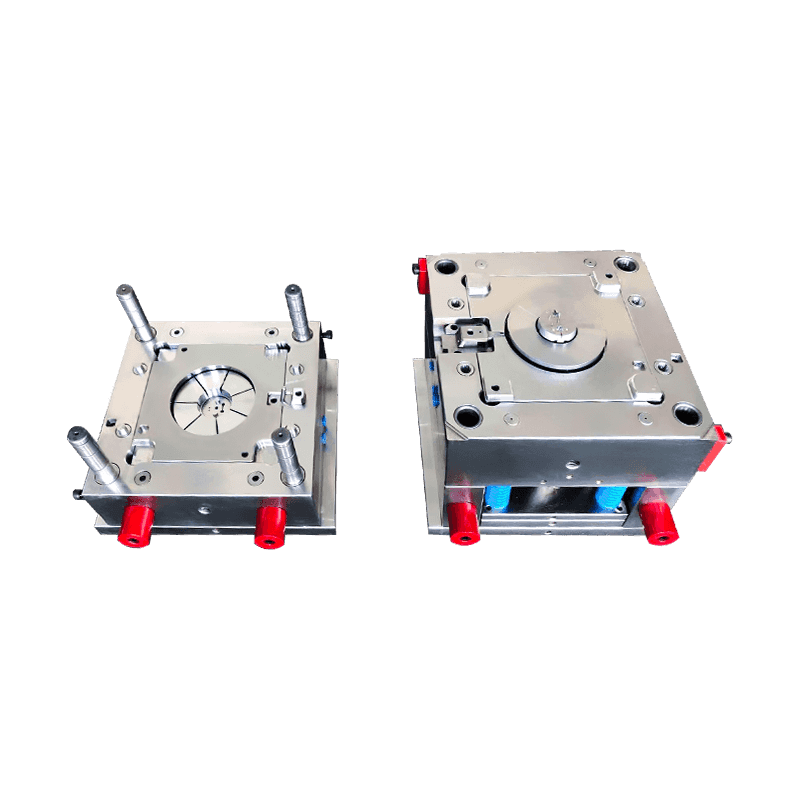

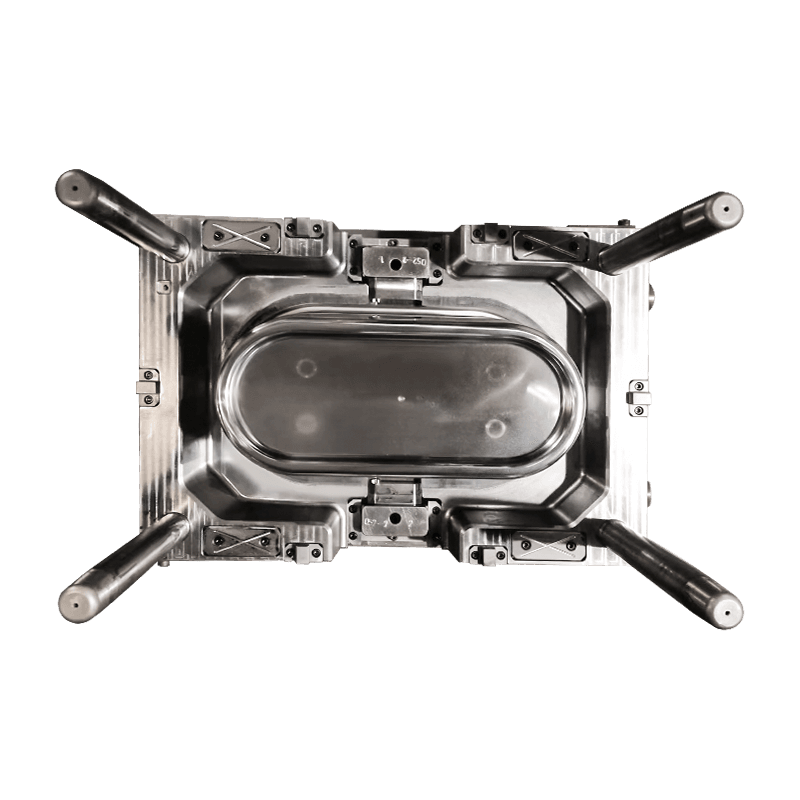

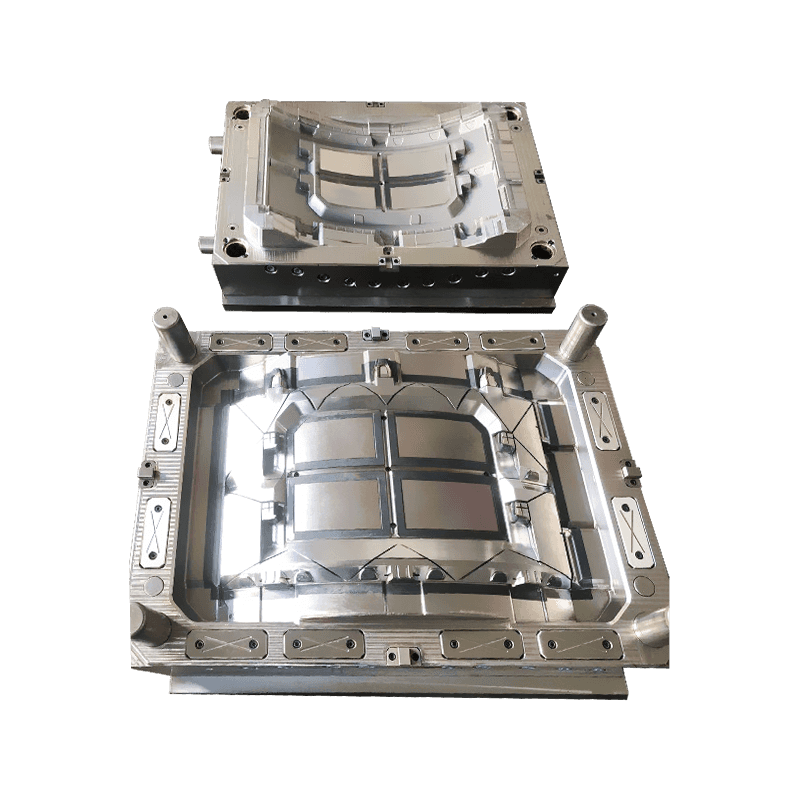

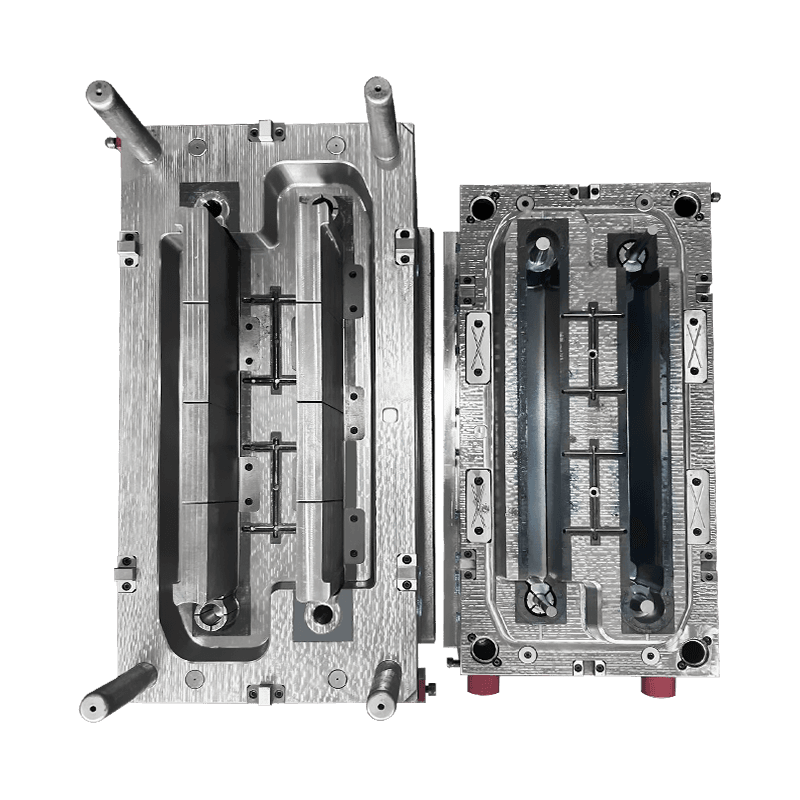

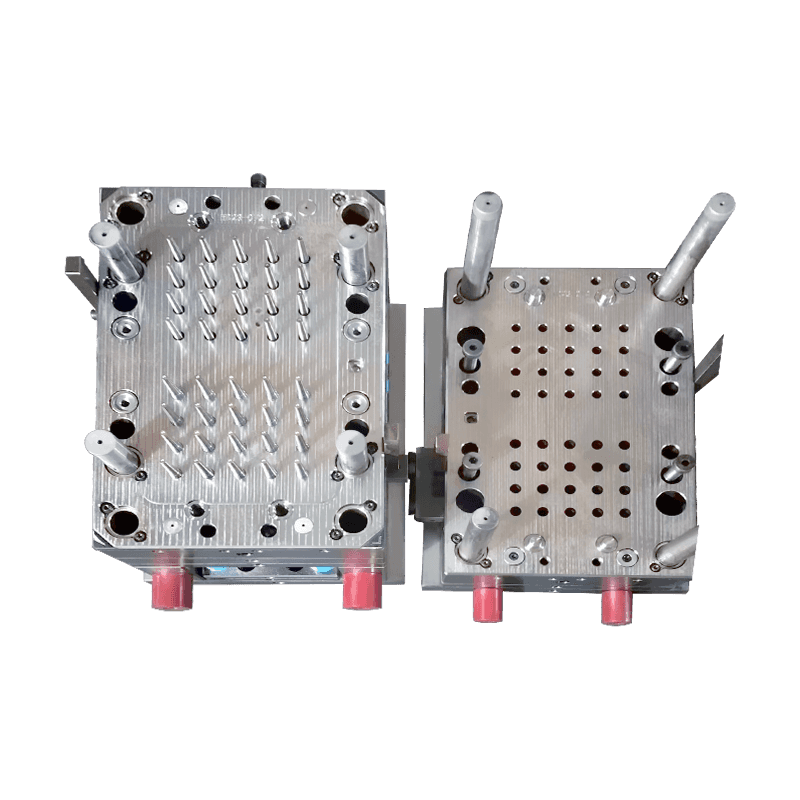

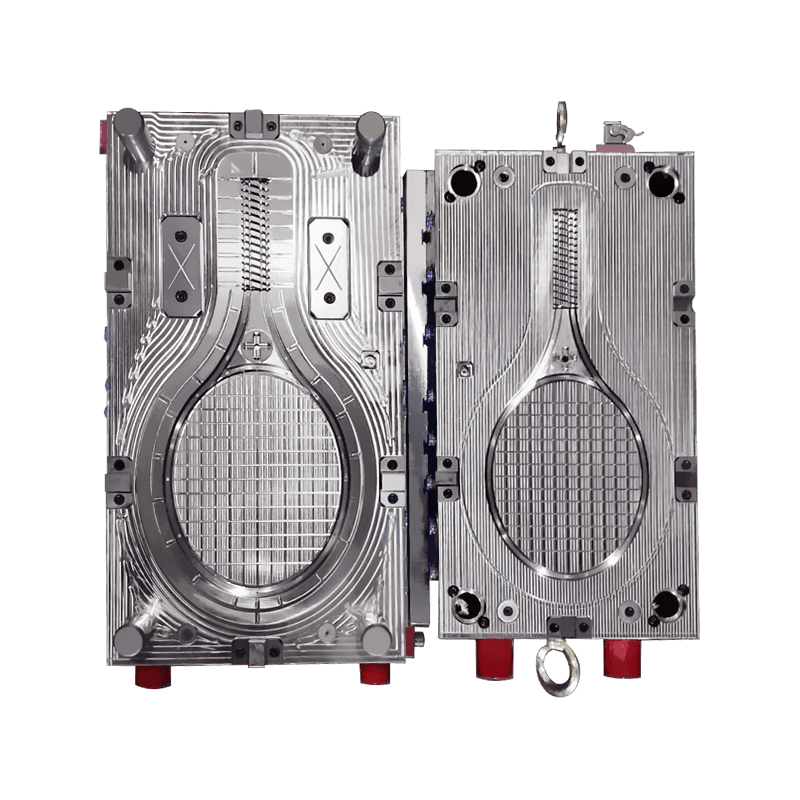

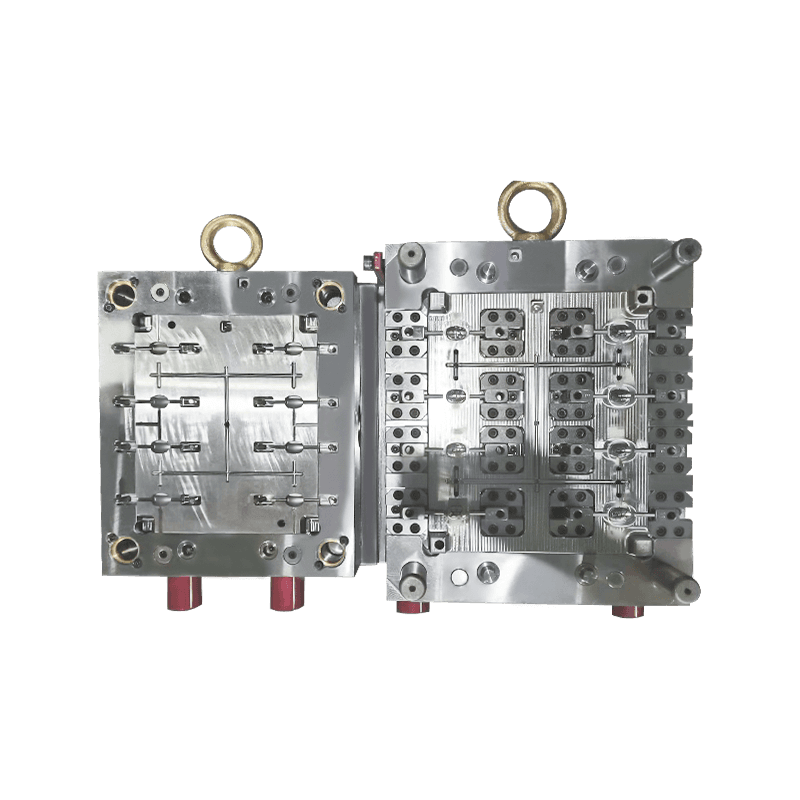

Tooling and Machining

Once the design is finalized, the Fruit Basket Die Casting Mold Factory's skilled machinists create the tooling for the mold. This involves precision machining of the mold components to ensure a good fit and smooth operation during the die casting process.

Die Casting

With the mold ready, the die casting process can begin. The Fruit Basket Die Casting Mold Factory uses high-quality aluminum or other suitable metals, which are melted and injected into the mold under high pressure. This process ensures that the metal fills the mold completely, creating a detailed and accurate fruit basket.

Post-Processing

After the die casting, the fruit basket is carefully removed from the mold. The Fruit Basket Die Casting Mold Factory then performs post-processing operations such as trimming, polishing, and finishing to ensure that the final product is free from defects and meets the desired aesthetic standards.

Applications of Fruit Basket Die Casting Molds

The practicality of fruit basket die casting molds is evident in the wide range of applications they serve. From household use to commercial settings, these molds enable the production of fruit baskets that are both functional and visually appealing.

English

English 中文简体

中文简体 русский

русский

Contact Us