Silicone plant pots have become increasingly popular in the gardening and home decor community due to their flexibility, durability, and aesthetic appeal. The process of creating these versatile pots involves a specialized tool known as the silicone plant pot injection mould tooling.

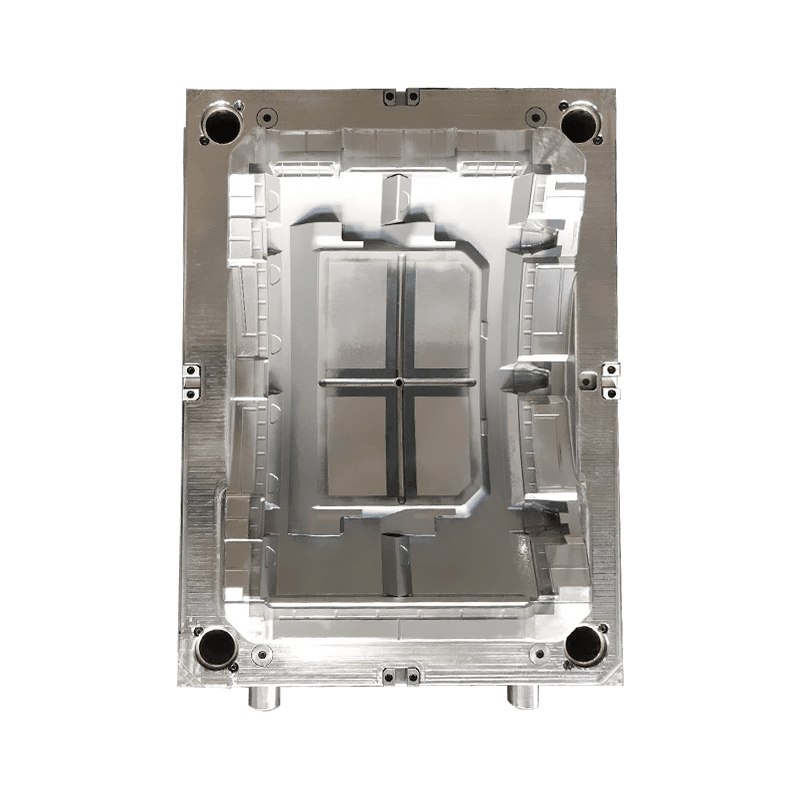

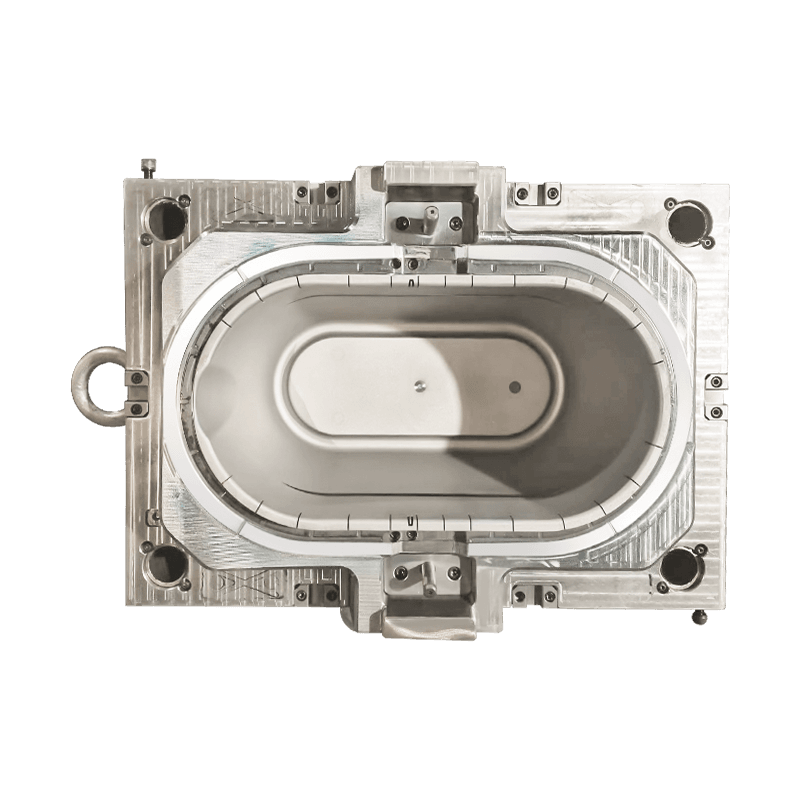

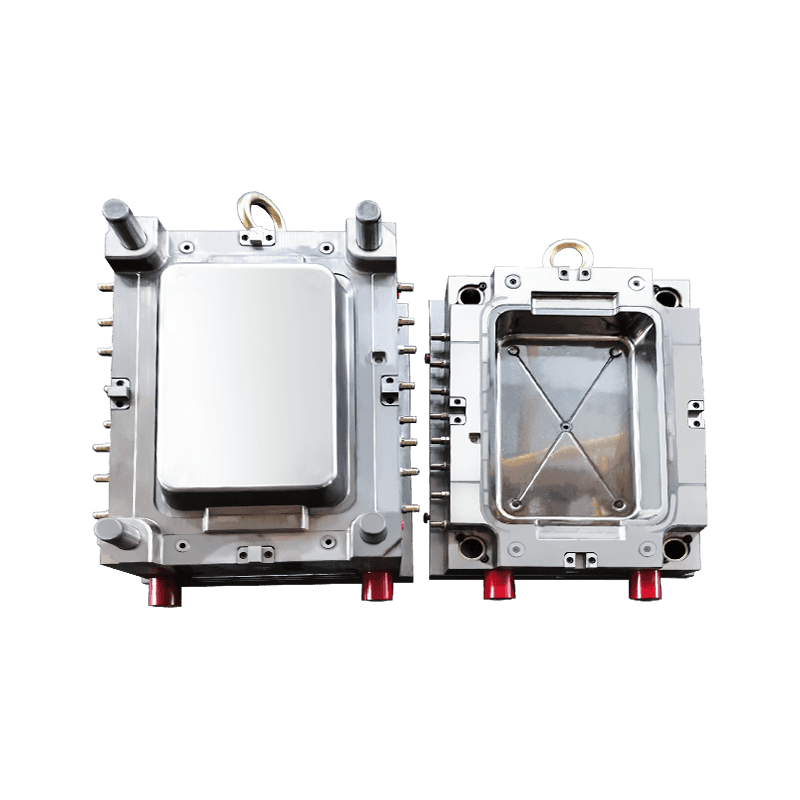

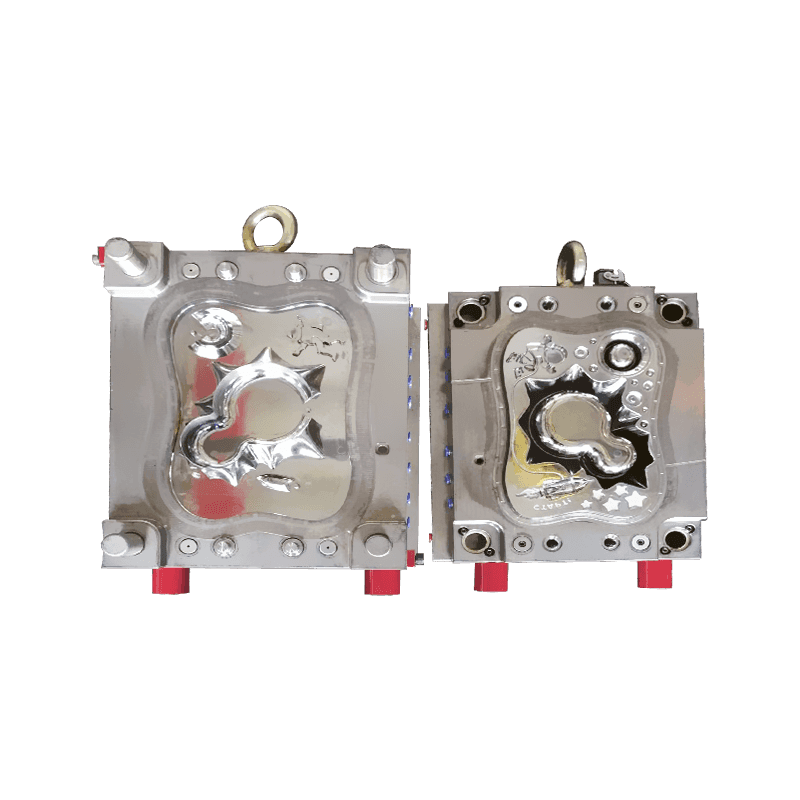

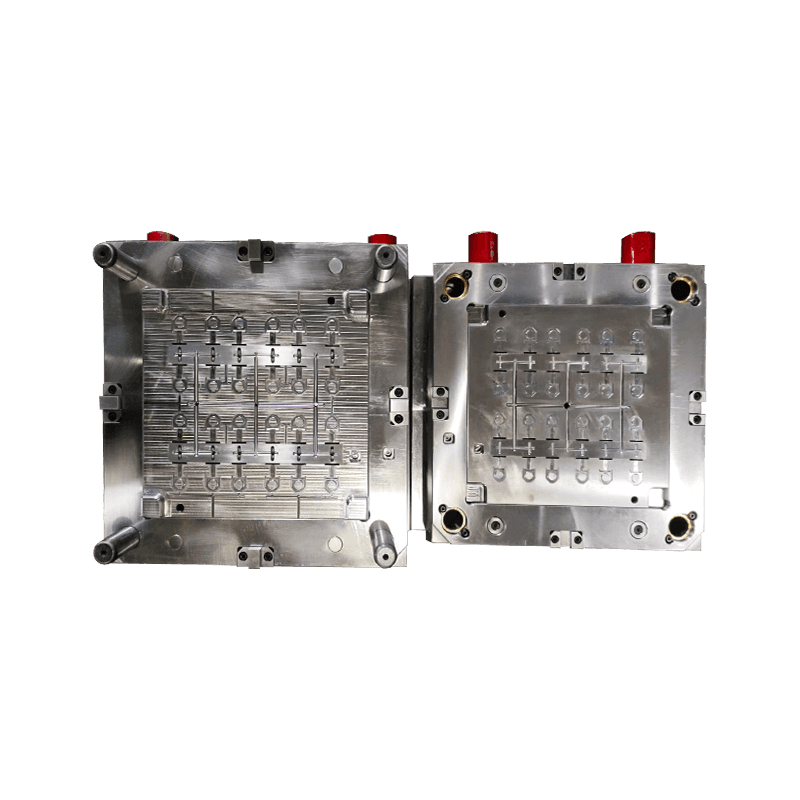

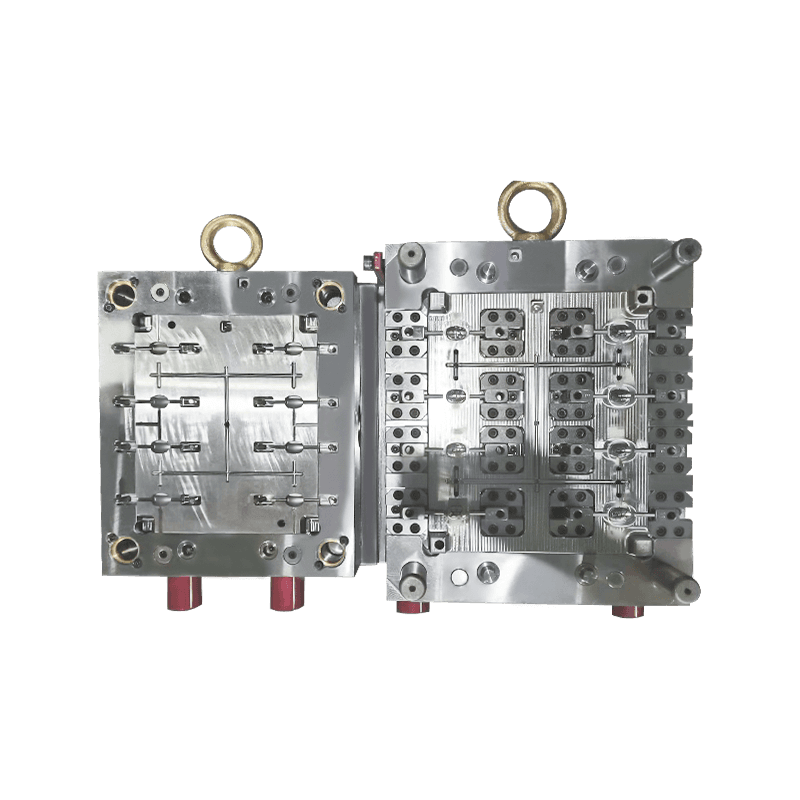

Silicone plant pot injection mould tooling is a precision-engineered tool designed to produce silicone plant pots through the injection moulding process. This process involves injecting liquid silicone rubber (LSR) into the mould, which then cures and forms the final product. The mould tooling is a critical component in ensuring the quality, consistency, and detail of the finished pots.

Components of Silicone Plant Pot Injection Mould Tooling

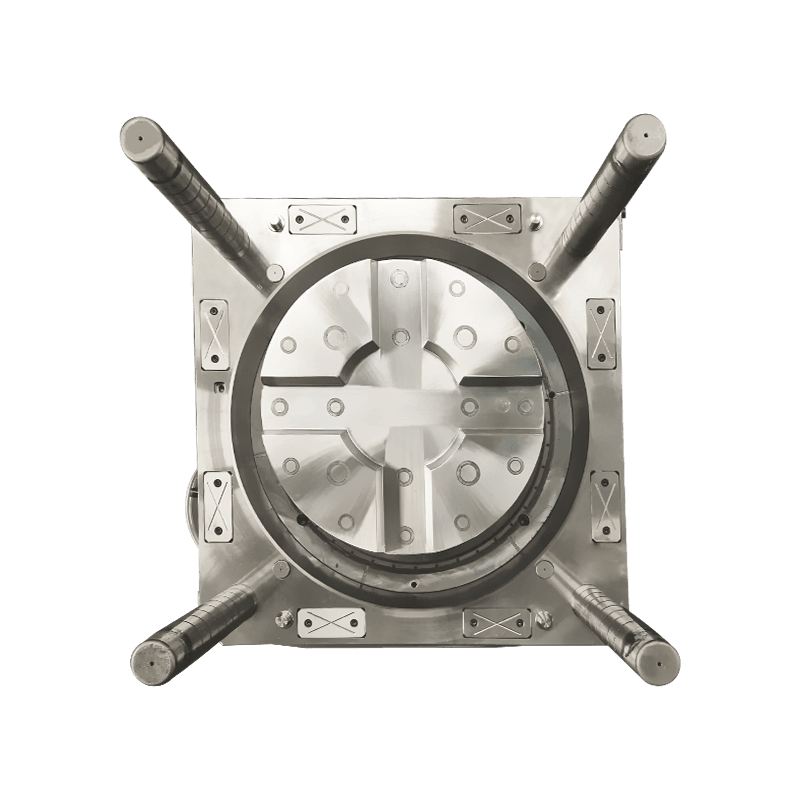

1. Cavity: The cavity is the heart of the mould tooling, where the silicone material is injected. It is designed to match the exact shape and dimensions of the final product.

2. Core: The core is a part of the mould that fits into the cavity and helps create the internal features of the silicone plant pot.

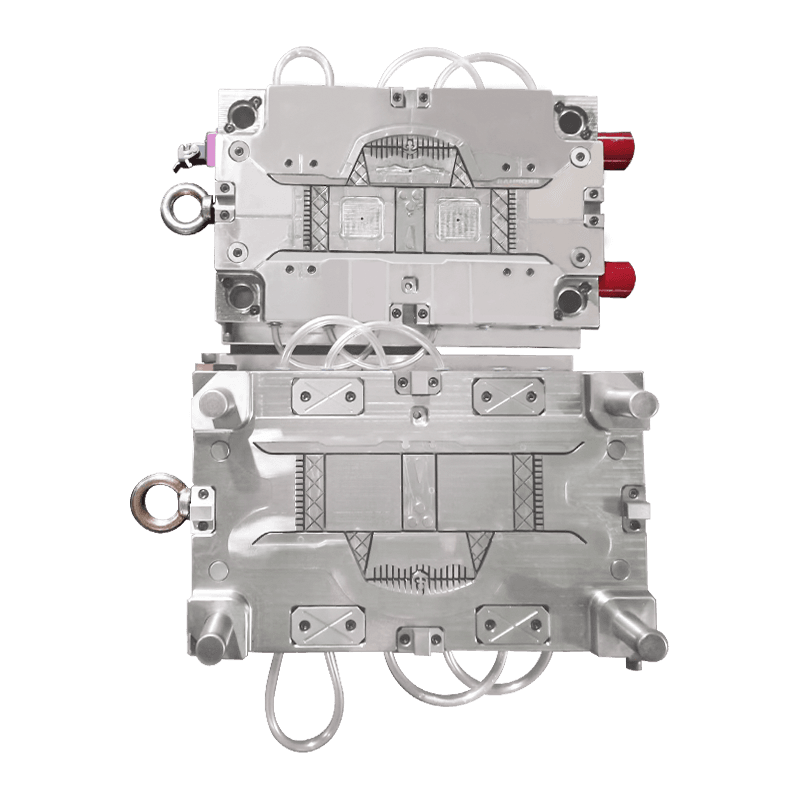

3. Gate: The gate is the entry point for the silicone material into the mould. It is strategically placed to material waste and ensure even distribution.

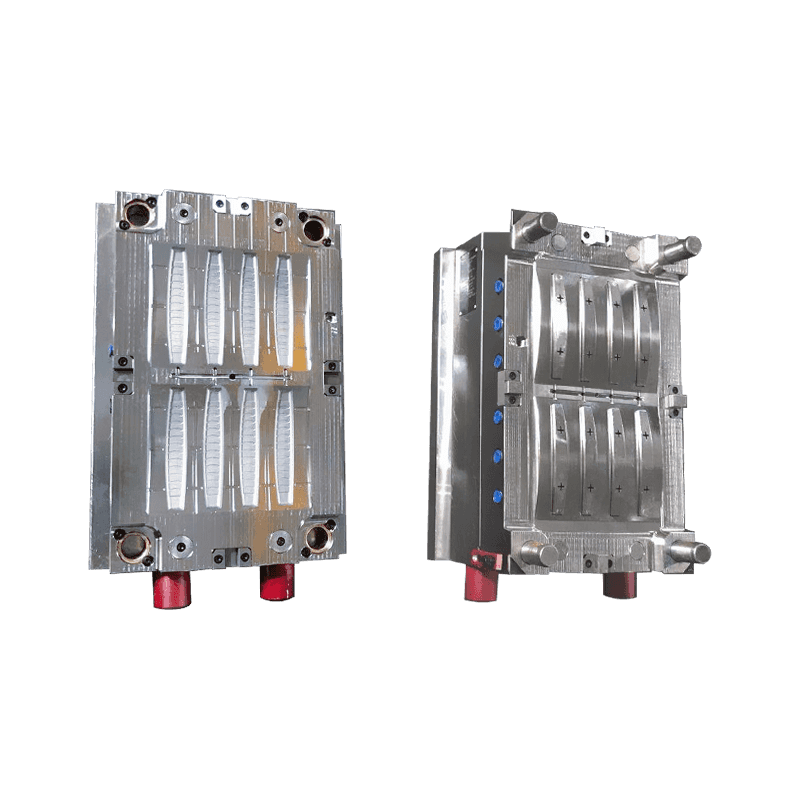

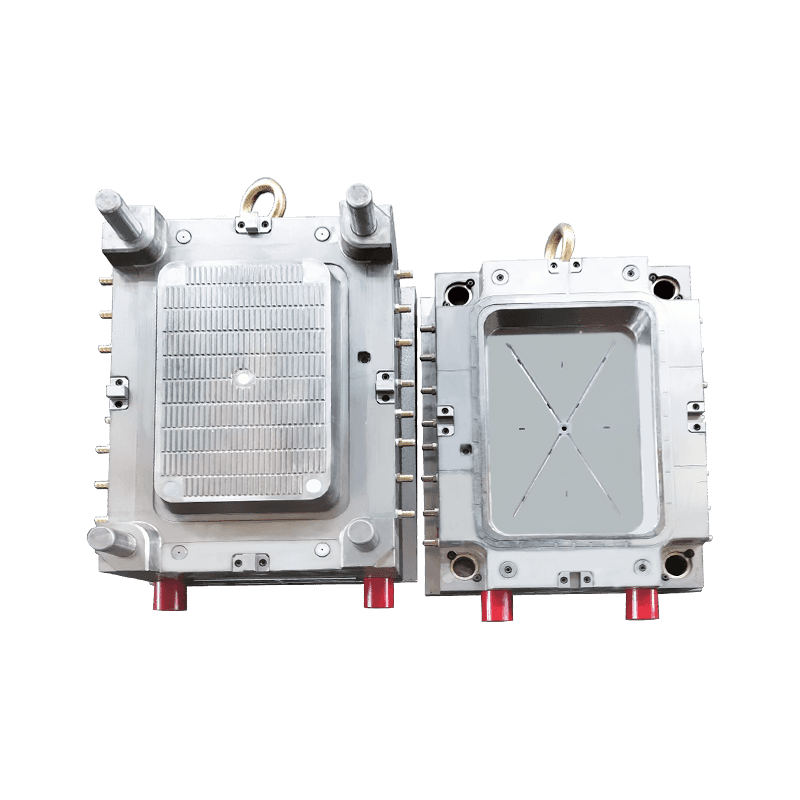

4. Runner System: The runner system is a network of channels that distribute the silicone material from the gate to the cavity. It is designed to reduce material waste and ensure uniform filling.

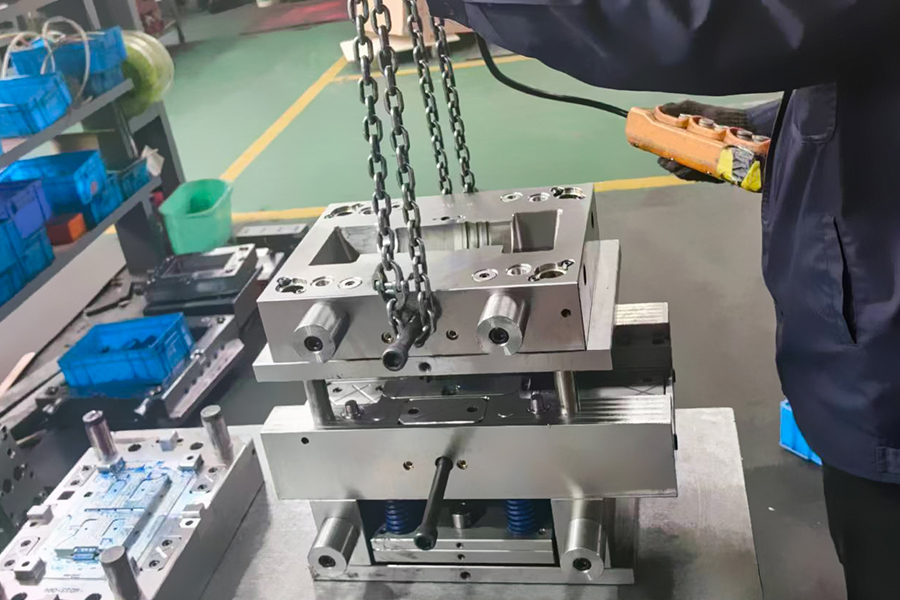

5. Ejection System: The ejection system is responsible for removing the finished silicone plant pot from the mould. It includes pins, plates, and springs that work together to safely eject the product.

6. Cooling System: A well-designed cooling system is essential for efficient production. It helps to cool the silicone material quickly, facilitating faster production cycles.

7. Heating System: The heating system ensures that the mould reaches the temperature for the injection of silicone material, promoting even curing and detail retention.

8. Parting Line: The parting line is the seam where the two halves of the mould meet. It must be designed to be as inconspicuous as possible to maintain the aesthetic appeal of the silicone plant pot.

9. Draft Angle: The draft angle is the angle at which the mould's sides are inclined to facilitate the easy removal of the silicone plant pot after the moulding process.

10. Vent System: The vent system allows for the escape of air and excess gases during the injection process, preventing air traps and ensuring a high-quality finish.

Importance of Silicone Plant Pot Injection Mould Tooling

The components of silicone plant pot injection mould tooling are not just technical parts; they are the foundation of a high-quality product. Each component plays a crucial role in the overall functionality and efficiency of the moulding process.

- Precision: The precision of the mould tooling ensures that every silicone plant pot produced is consistent in size, shape, and detail.

- Durability: High-quality materials and construction of the mould tooling contribute to its durability, allowing for long-term use without loss of quality.

- Flexibility: The design of the mould tooling allows for flexibility in the types of silicone plant pots that can be produced, catering to various market demands.

- Efficiency: The mould tooling is designed to optimize the injection moulding process, reducing production time and increasing output.

- Aesthetics: The attention to detail in the mould tooling ensures that the silicone plant pots have a smooth, professional finish that appeals to consumers.

The Role of Silicone Plant Pot Injection Mould Tooling in Modern Gardening

Silicone plant pot injection mould tooling has revolutionized the gardening industry by providing a modern, versatile, and visually appealing solution for plant care. The use of silicone in plant pots offers several advantages:

- Flexibility: Silicone's flexible nature allows for easy handling and transportation of the pots.

- Durability: Silicone is resistant to weathering, making it an ideal material for outdoor use.

- Non-Toxic: Silicone is non-toxic and safe for plants, ensuring a healthy environment for plant growth.

- Variety: The mould tooling allows for a wide range of designs and sizes, catering to different gardening needs and preferences.

English

English 中文简体

中文简体 русский

русский

Contact Us