We are committed to providing customers with high-quality, precision mold solutions.

Toolbox Molds

Cat:Toolbox And Accessories Mold

Toolbox molds encompass a variety of types designed to produce different styles and sizes of toolbox...

See Details

China Thermoplastic Molds in Thermo Molding Plastic for Sale

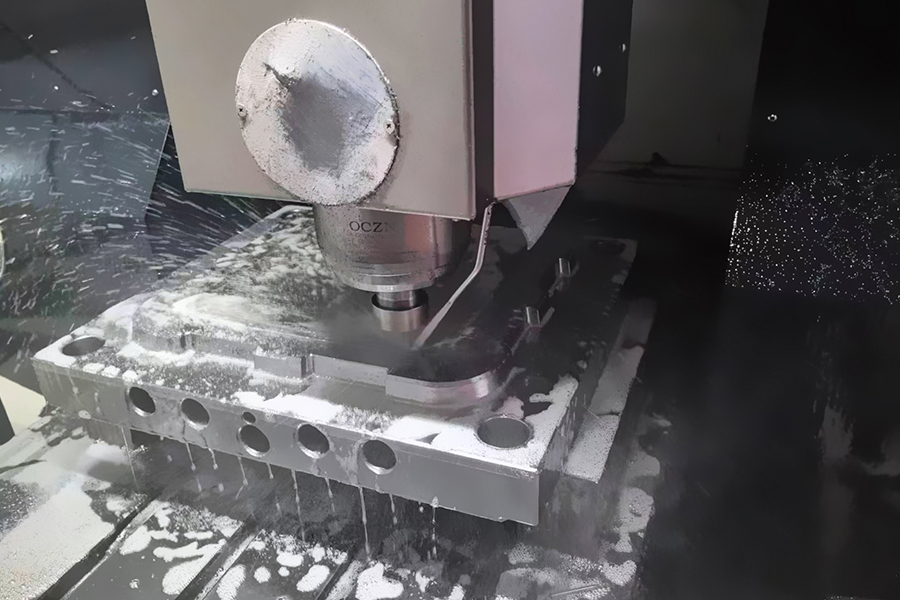

Thermoplastic molds have rapidly gained popularity in various manufacturing processes, particularly in thermo molding plastic applications. These molds, which are made from thermoplastic materials, offer several advantages that have revolutionized the production of plastic parts across numerous industries, from automotive to medical devices. By exploring the benefits of thermoplastic molds, it becomes clear why they are becoming the go-to choice for businesses looking for durability, flexibility, and cost-effectiveness.

Durability and Longevity

One of the primary advantages of using thermoplastic molds in thermo molding plastic applications is their exceptional durability. Thermoplastic materials, unlike traditional metal molds, exhibit resistance to wear and tear. This is especially important in industries where molds must undergo high volumes of use and harsh conditions. The robust nature of thermoplastic molds allows for an extended service life compared to their metal counterparts, reducing the need for frequent replacements and saving on long-term maintenance costs. Additionally, these molds maintain their performance even under high temperatures, making them ideal for thermo molding plastic processes where heat is a critical factor.

Flexibility in Design and Manufacturing

Flexibility is another significant advantage of thermoplastic molds in the thermo molding plastic industry. Thermoplastic materials are easier to shape and manipulate, which allows for intricate and precise designs that might not be feasible with metal molds. This flexibility enables manufacturers to create complex shapes, finer details, and customized components that meet specific customer needs. Whether it's producing lightweight automotive parts, delicate medical components, or intricate consumer goods, thermoplastic molds provide the necessary precision and adaptability required for modern manufacturing.

Additionally, thermoplastic molds can accommodate different types of plastics, such as polyethylene, polypropylene, and PVC. This versatility makes them suitable for a wide range of applications, further expanding their utility in various industries. Unlike traditional molds, which may be limited by material compatibility, thermoplastic molds can be easily adjusted to handle a broader spectrum of plastics, reducing the complexity of the production process.

Cost-Effectiveness and Efficiency

Cost-efficiency is a critical factor that makes thermoplastic molds a highly attractive choice for manufacturers. While initial tooling costs for thermoplastic molds may be higher than traditional molds, their ability to produce high-quality, complex parts without compromising on speed leads to lower overall production costs. The reduced wear and tear associated with thermoplastic molds also means fewer maintenance and replacement costs, contributing to long-term savings.

Furthermore, the rapid production speed of thermoplastic molds in thermo molding plastic applications helps businesses meet increasing demand without sacrificing quality. Thermo molding plastic processes are known for their quick turnaround times, which can be a significant advantage in industries that require large quantities of products in a short amount of time. The ability to scale production with minimal delays makes thermoplastic molds a highly effective solution for companies striving to maintain competitive pricing while ensuring consistent product quality.

Environmental Benefits

Thermoplastic molds are also more environmentally friendly compared to metal molds, as they are often made from recyclable materials. The thermo molding plastic process is inherently more sustainable, as the plastic used can be easily recycled and reused. This reduction in material waste is an appealing factor for industries focused on sustainability and reducing their carbon footprint. Additionally, thermoplastic molds can be reused many times, further contributing to the sustainability of the manufacturing process.

Contact Us