We are committed to providing customers with high-quality, precision mold solutions.

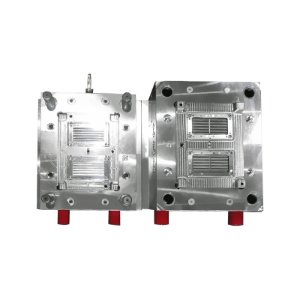

Duct Exhaust Fan Shell Mold

Cat:Ventilation Mold

The duct exhaust fan shell mold is a special mold used to produce the duct exhaust fan shell. It use...

See Details

Ventilation grille molds play a crucial role in modern ventilation systems, ensuring airflow while contributing to the overall design and aesthetics of buildings. These molds are specially designed to produce durable, high-quality ventilation grilles that are essential for air circulation in both residential and commercial spaces. Understanding the manufacturing process and design requirements for these molds can help businesses and engineers make informed decisions when selecting the right solutions for their projects.

1. The Manufacturing Process of Ventilation Grille Molds The production of ventilation grille molds involves several key steps, starting from the initial design phase to the final production and testing of the molds. Thestep in creating these molds is to understand the specific requirements of the project. This includes considering the size, shape, airflow capacity, and aesthetic preferences of the ventilation grille.

Once the design is finalized, advanced manufacturing techniques such as precision molding, CNC machining, and metal casting are employed to ensure high accuracy and consistency in the final product. The use of high-quality materials like stainless steel, aluminum, or durable plastics is essential to ensure the longevity and durability of the ventilation grille molds.

2. Key Design Considerations for Ventilation Grille Molds Designing ventilation grille molds requires a deep understanding of both functional and aesthetic aspects. The mold needs to be carefully engineered to ensure that it can withstand the pressures of high airflow and potential environmental factors like humidity and temperature changes. Additionally, the design should account for ease of installation and maintenance.

Some of the important design features to consider include:

Airflow efficiency: The mold should create ventilation grilles that allow for airflow without obstructing the system's efficiency.

Durability: The materials used in the mold must be resistant to wear and tear, as the grilles will be exposed to frequent airflow and, in some cases, harsh environmental conditions.

Aesthetics: The design of the ventilation grille molds should complement the architectural style of the building, ensuring that the grilles blend seamlessly with the interior or exterior.

3. Materials Used in Ventilation Grille Molds Selecting the right material is critical for both the ventilation grille mold's functionality and its longevity. Some commonly used materials for these molds include:

Stainless steel: Known for its strength and corrosion resistance, making it ideal for both indoor and outdoor applications.

Aluminum: A lightweight, cost-effective material with good resistance to corrosion and suitable for a variety of mold designs.

Plastic composites: These materials are often used in mold designs that require flexibility, lightweight characteristics, and resistance to certain chemicals.

Each material type offers its own set of advantages, and the choice depends on the specific application and environmental factors.

4. Customization and OEM Services for Ventilation Grille Molds In today's market, many businesses seek custom ventilation grille molds to meet specific project requirements. This is where OEM/ODM services come into play. OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services allow companies to create bespoke molds tailored to their exact specifications. This customization can include adjustments to mold size, shape, material, and even airflow characteristics.

These custom ventilation grille molds are particularly beneficial for projects that require unique designs or have specific functional needs, such as high-traffic areas or spaces with high humidity.

5. The Importance of Quality Control in Ventilation Grille Mold Manufacturing Quality control is a critical aspect of manufacturing ventilation grille molds. To ensure that the molds meet the necessary standards for performance and durability, manufacturers implement strict testing protocols. This can include pressure tests, dimensional inspections, and corrosion resistance tests. Ensuring that each mold is manufactured to exact specifications helps prevent defects and guarantees a longer lifespan for the finished ventilation grilles.

The manufacturing process for ventilation grille molds is a complex and precise undertaking that requires a balance of design expertise, quality materials, and advanced production techniques. Whether opting for off-the-shelf models or customizing molds through OEM/ODM services, understanding the production process can help businesses select the ventilation grille molds for their specific needs. With the right molds, companies can improve airflow efficiency and enhance the aesthetic appeal of their ventilation systems.

Contact Us