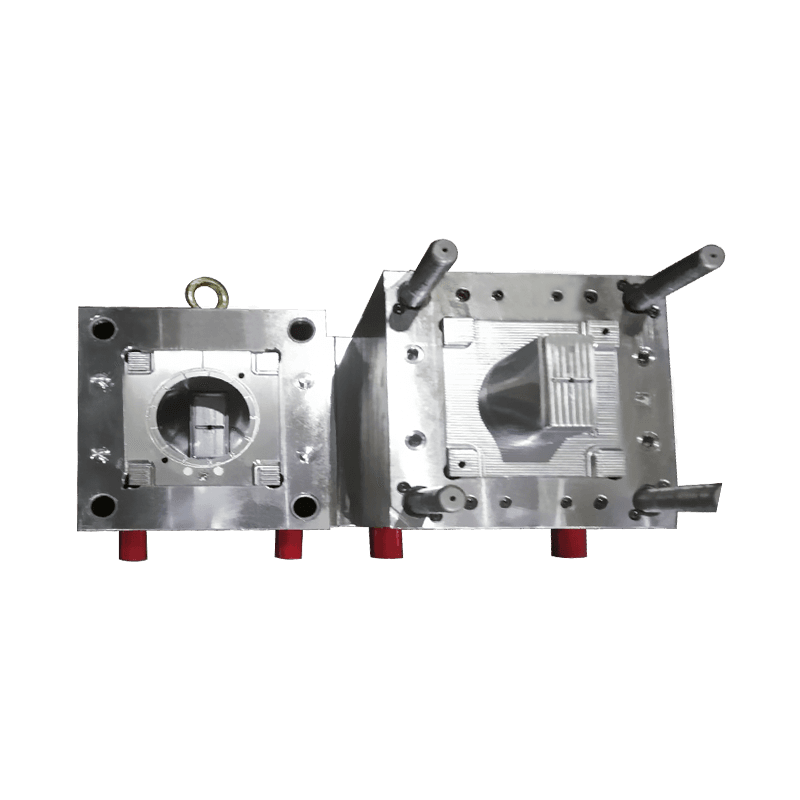

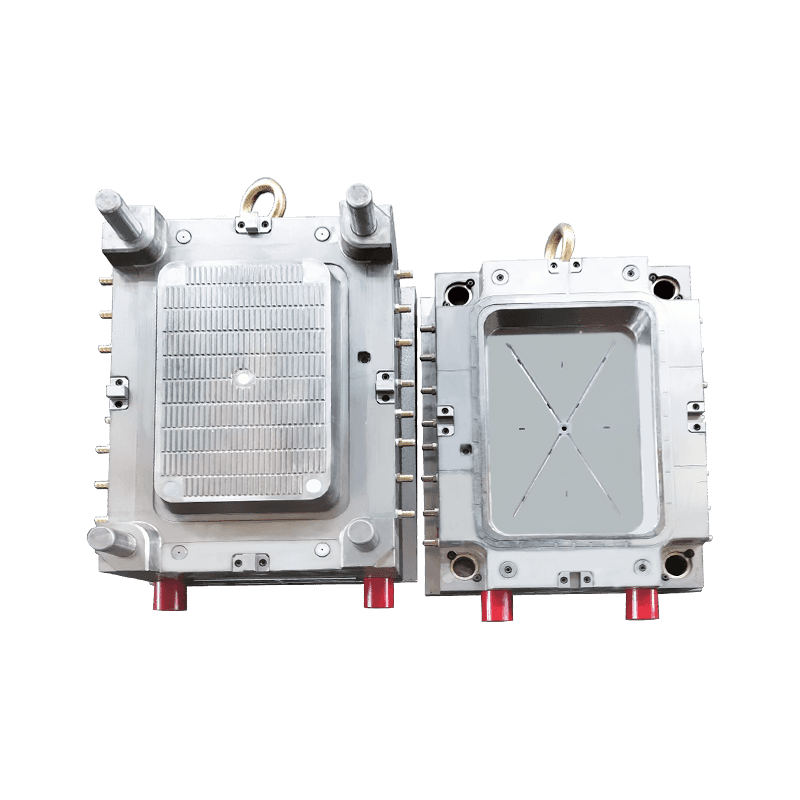

OEM Toolbox Storage Box Lid Molds Company Price For Sale

The advantages of toolbox storage box lid molds go beyond just shaping plastic or metal lids; they contribute to cost efficiency, customization, durability, and production consistency.

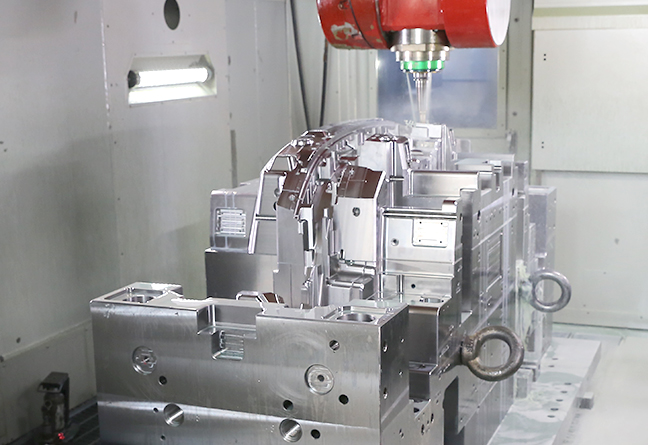

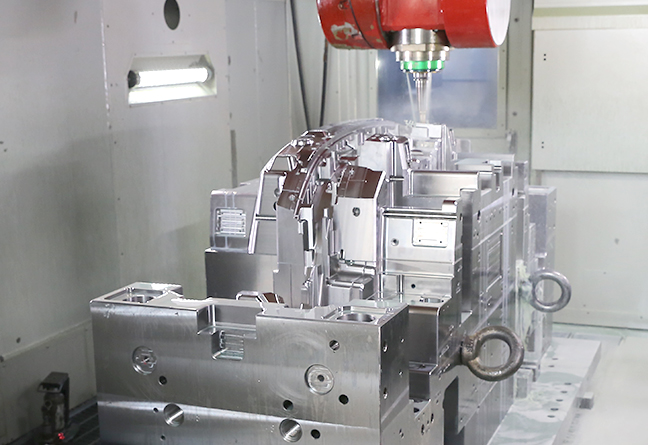

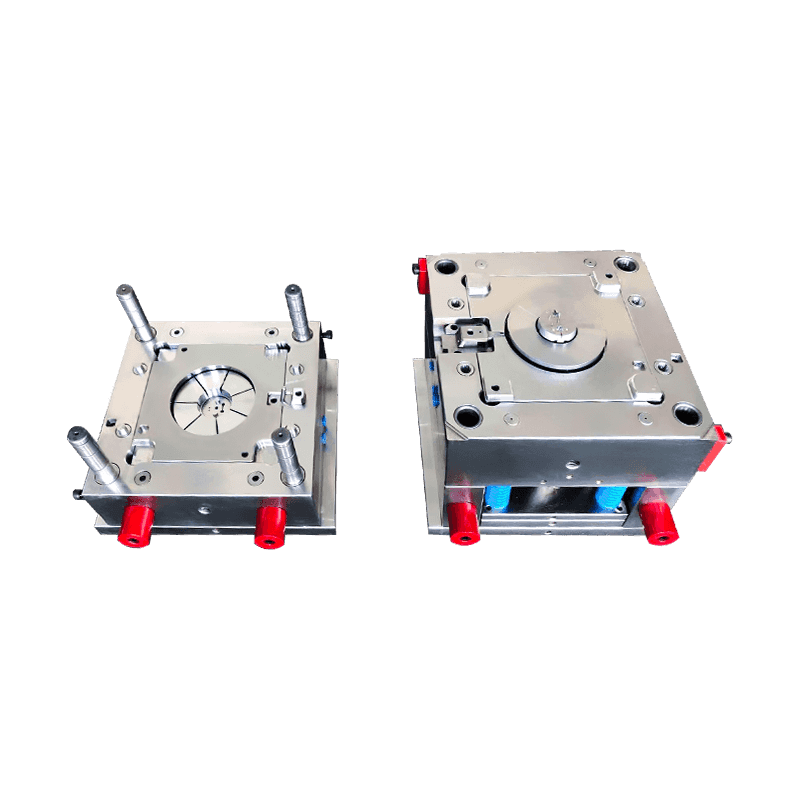

1. High Precision and Consistency

One of the significant advantages of toolbox storage box lid molds is their ability to produce identical lids with high precision.

Uniform dimensions: The molds ensure that each lid is manufactured with accurate dimensions, ensuring a fit for the toolbox.

Consistency in mass production: Whether producing hundreds or thousands of lids, toolbox storage box lid molds maintain uniformity in design and size.

Minimized defects: High-quality molds reduce errors such as warping, improper thickness, or misalignment, fewer rejected parts and better overall quality.

2. Durability and Strength

Toolboxes are often exposed to harsh conditions, including heavy loads, impact, and temperatures. The lids, therefore, need to be strong and resilient.

Impact resistance: Molds allow for the production of lids made from reinforced materials that can withstand pressure and rough handling.

Weather resistance: Toolbox storage box lid molds can create lids resistant to UV rays, moisture, and temperature fluctuations, making them suitable for outdoor use.

Long lifespan: The use of durable materials such as ABS plastic, polypropylene, or even metal ensures that lids do not crack or wear out quickly.

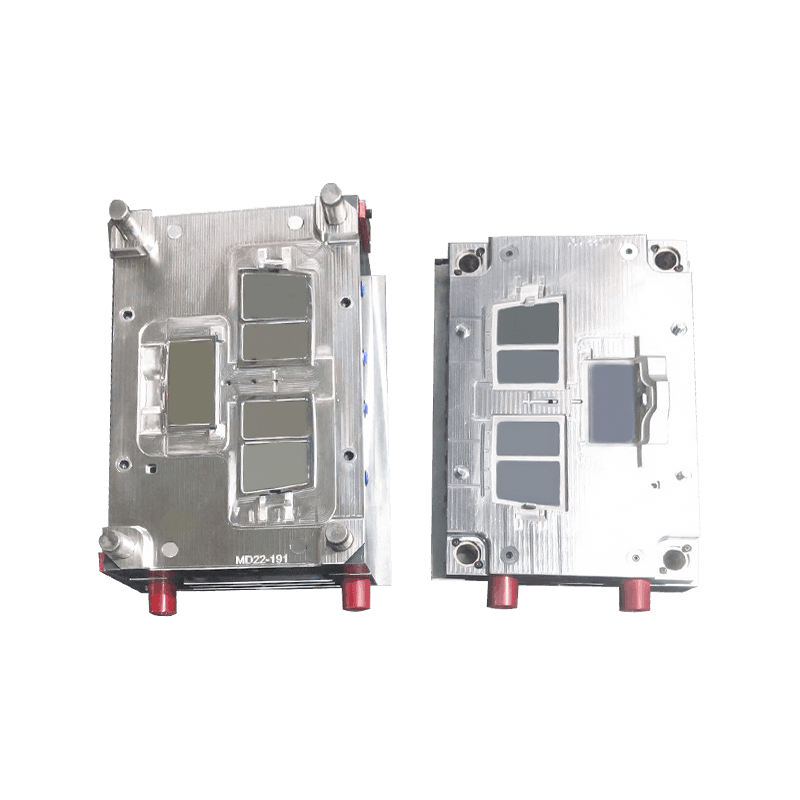

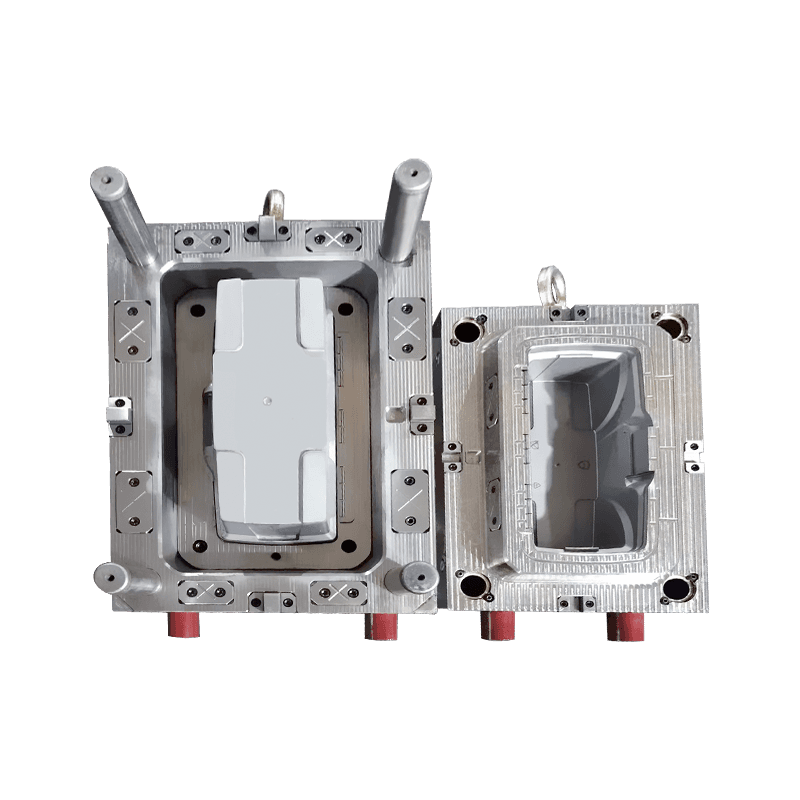

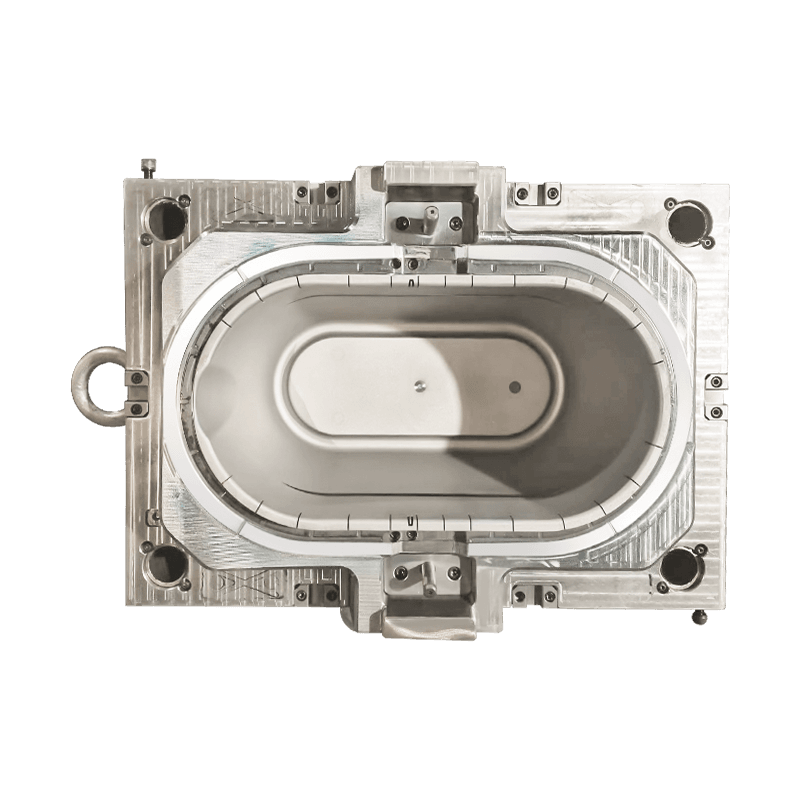

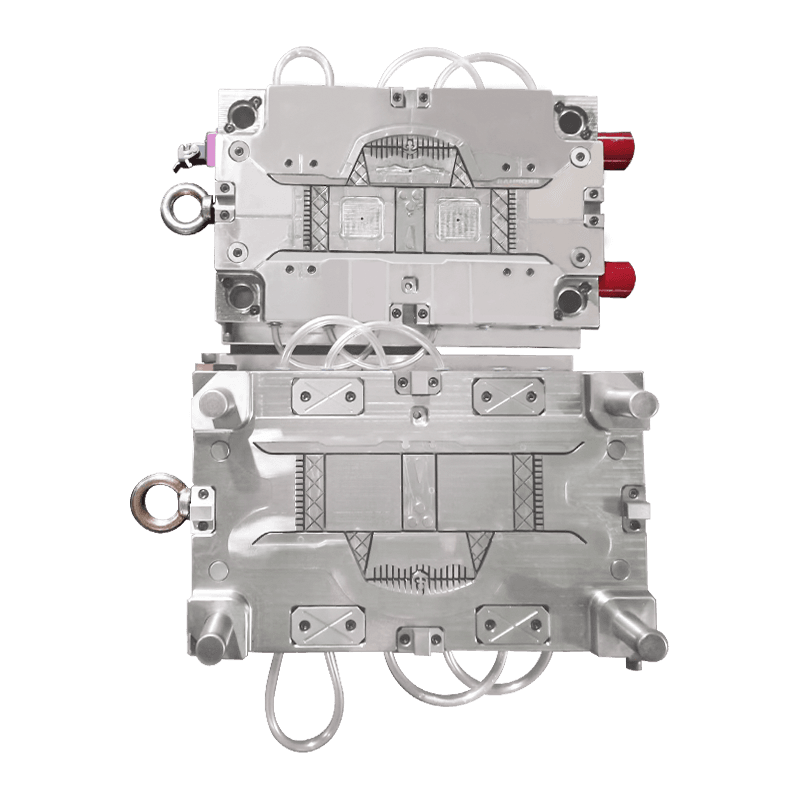

3. Customization and Design Flexibility

Another advantage of toolbox storage box lid molds is their ability to produce lids in a variety of shapes, sizes, and designs to meet different user requirements.

Variety of sizes: Molds can be customized to create lids for small, medium, and large toolboxes.

Branding and aesthetics: Companies can incorporate their logos, patterns, or unique textures on the lids for a personalized touch.

Specialized features: Molds can be designed to create lids with built-in handles, locks, or compartments to enhance functionality.

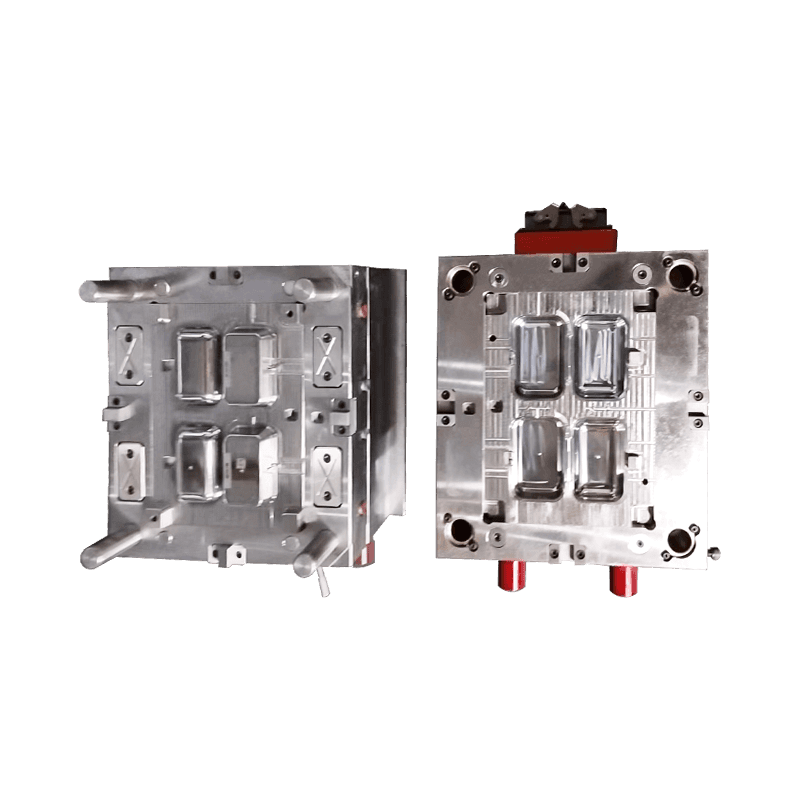

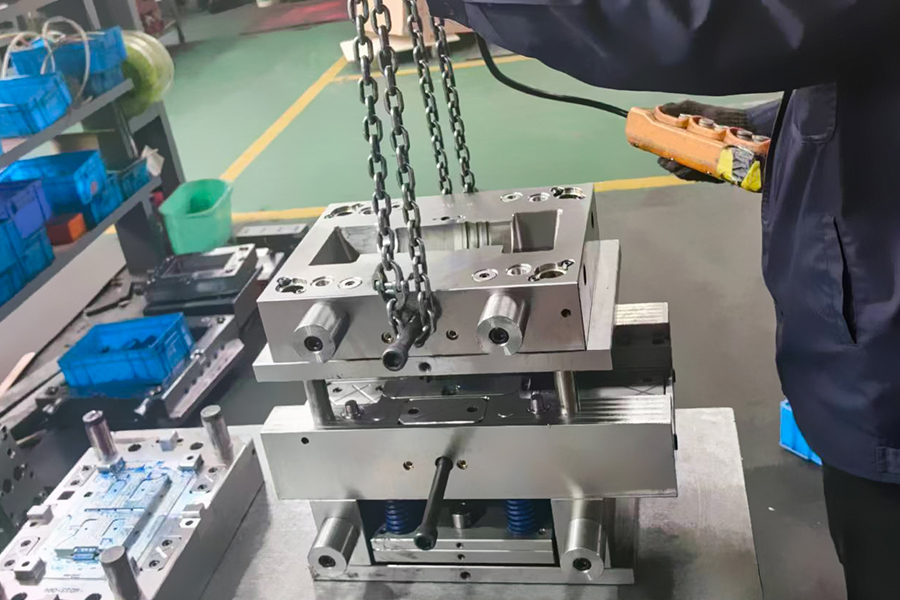

4. Cost Efficiency in Manufacturing

Using toolbox storage box lid molds significantly improves production efficiency, reducing manufacturing costs in the long run.

High-speed production: Once a mold is created, it can produce thousands of lids at a rapid pace.

Reduced material waste: Injection molding processes optimize material usage, excess waste.

Lower labor costs: Automated molding systems require minimal human intervention, reducing workforce expenses.

Long-term savings: A well-made mold has a long lifespan and can be used for multiple production cycles, making it a cost-effective investment.

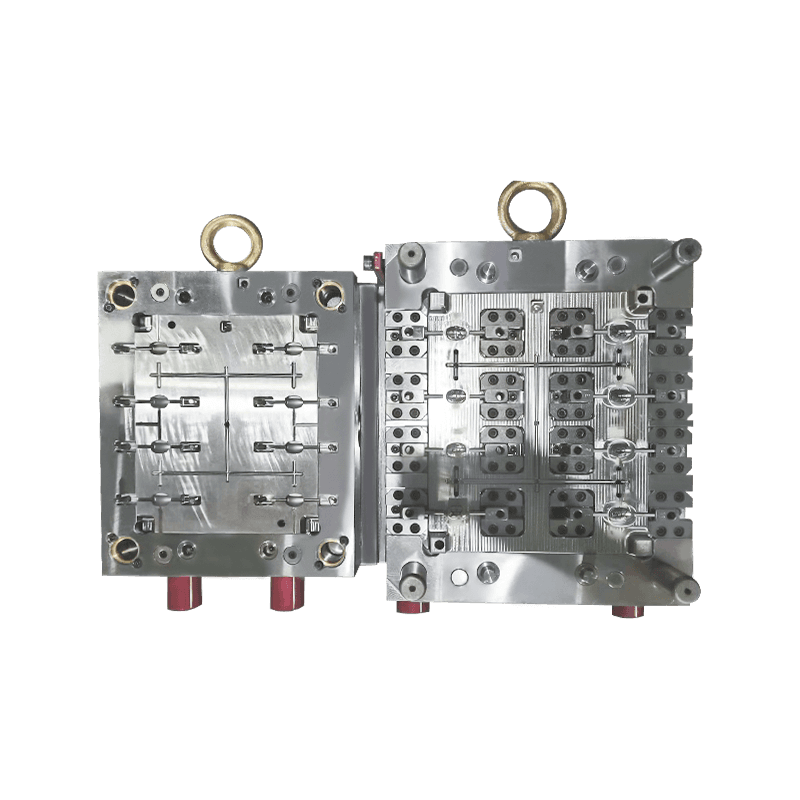

5. Compatibility with Various Materials

Depending on the application, toolbox storage box lid molds can be designed to work with different materials, providing versatility in production.

Plastic molds: Commonly used for lightweight, impact-resistant lids made from ABS, polypropylene, or polyethylene.

Metal molds: Used for producing aluminum or steel lids that offer durability and security.

Hybrid designs: Some molds allow for the integration of plastic and metal components, offering a balance between strength and weight.

6. Enhanced Safety Features

Safety is a crucial aspect of toolbox design, and toolbox storage box lid molds help in creating lids with built-in security measures.

Locking mechanisms: Molds can be designed to incorporate locks or latches for added security.

Child-resistant features: Some lids are molded with safety locks to prevent accidental access.

Anti-slip surfaces: Textured lid surfaces improve grip and prevent slips when opening or closing the toolbox.

7. Environmental Sustainability

With growing environmental concerns, manufacturers are seeking eco-friendly solutions in production. Toolbox storage box lid molds contribute to sustainability in several ways:

Use of recycled materials: Many toolbox lids are now manufactured using recycled plastics, reducing waste.

Energy-efficient production: Modern molding techniques consume less energy, lowering the carbon footprint.

Recyclability: Lids produced with high-quality molds can be recycled at the end of their lifespan, promoting a circular economy.

English

English 中文简体

中文简体 русский

русский

Contact Us