Gardening is an art form that combines the beauty of nature with the creativity of human design. One of the key elements in this art is the plant pot, which not only serves as a vessel for nurturing plants but also as a decorative piece that enhances the visual appeal of any space.

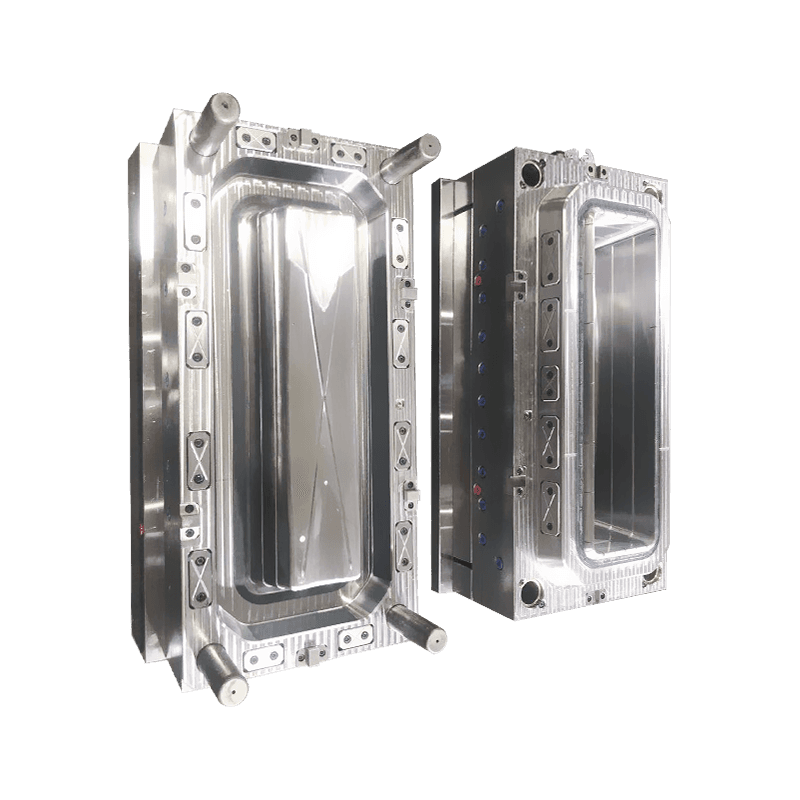

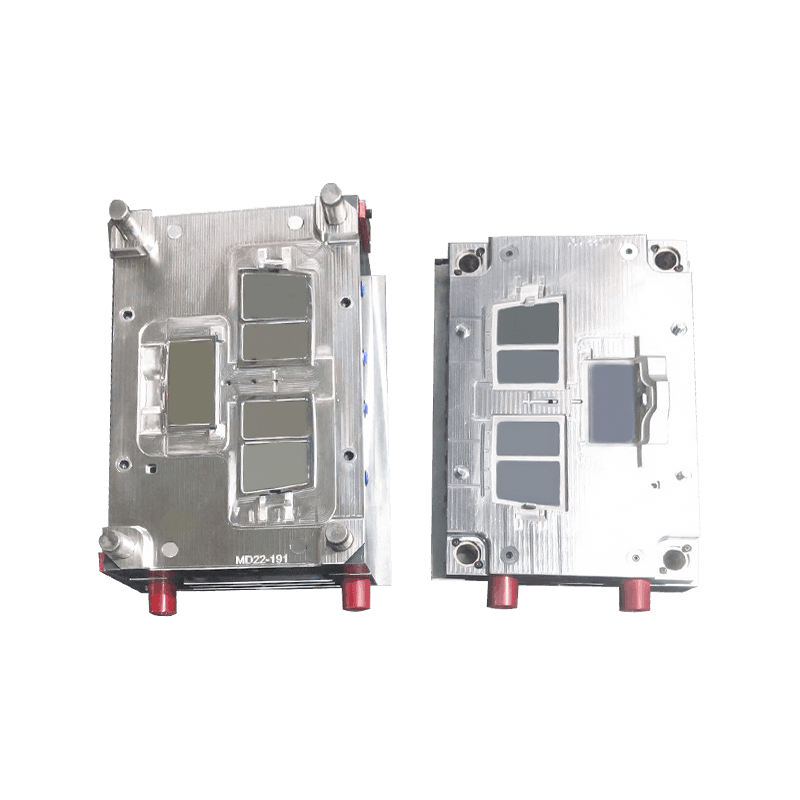

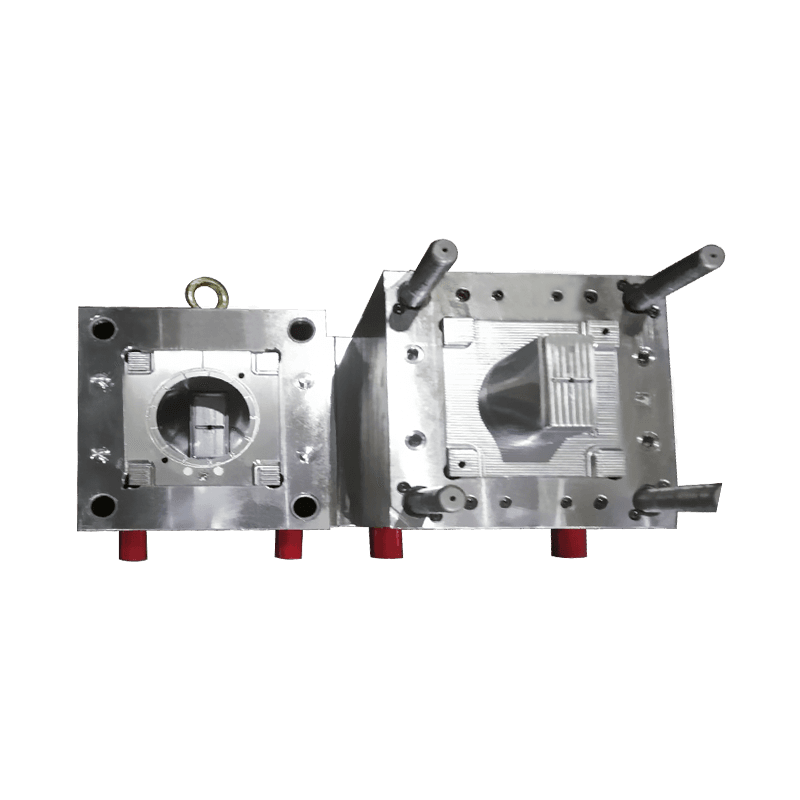

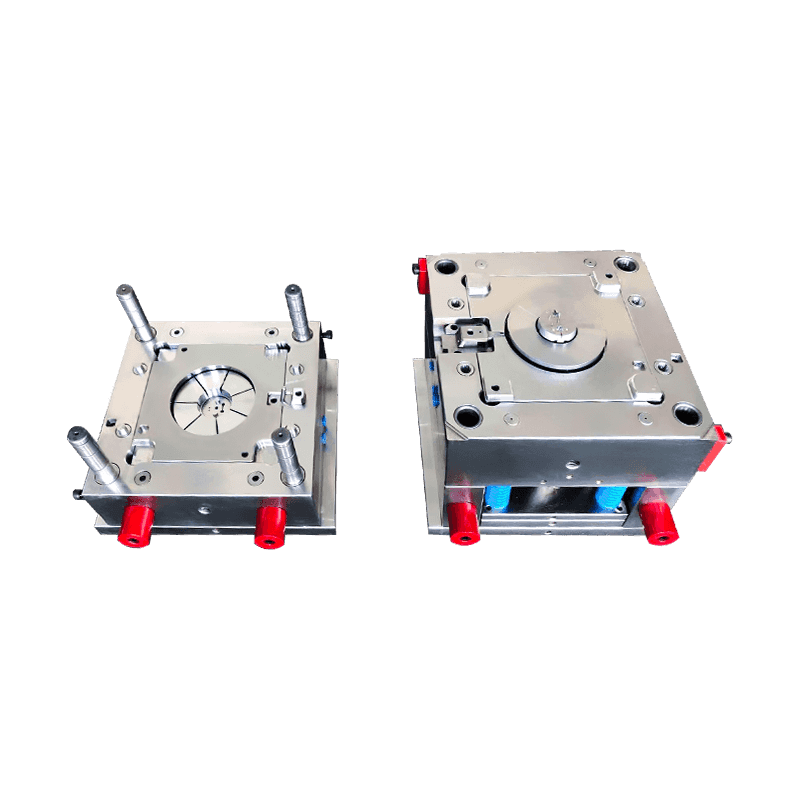

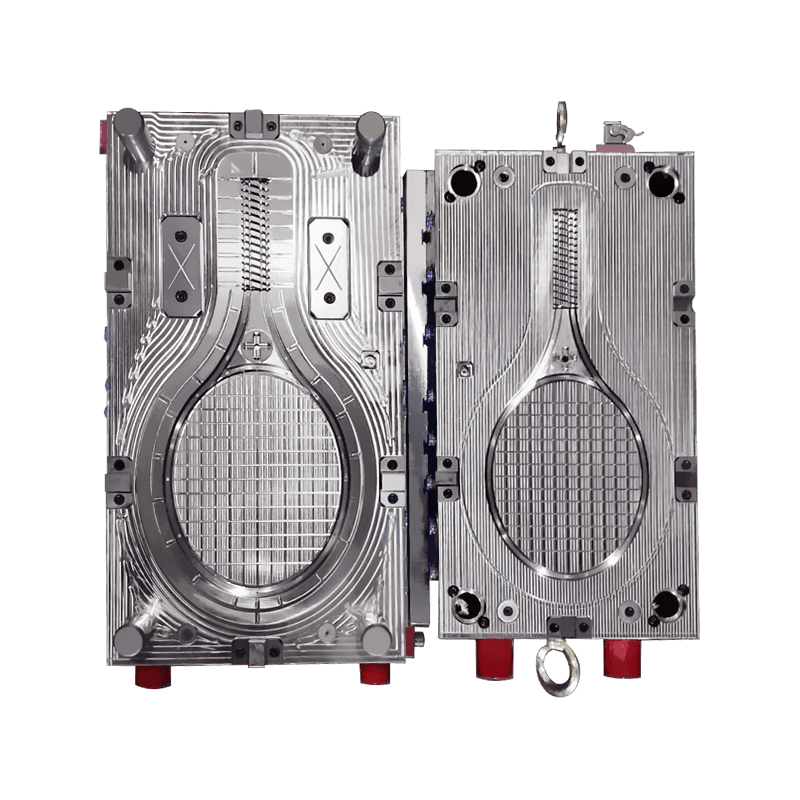

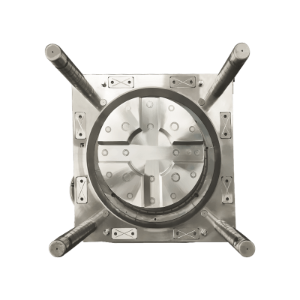

Large Plant Pot Plastic Injection Molding Mold

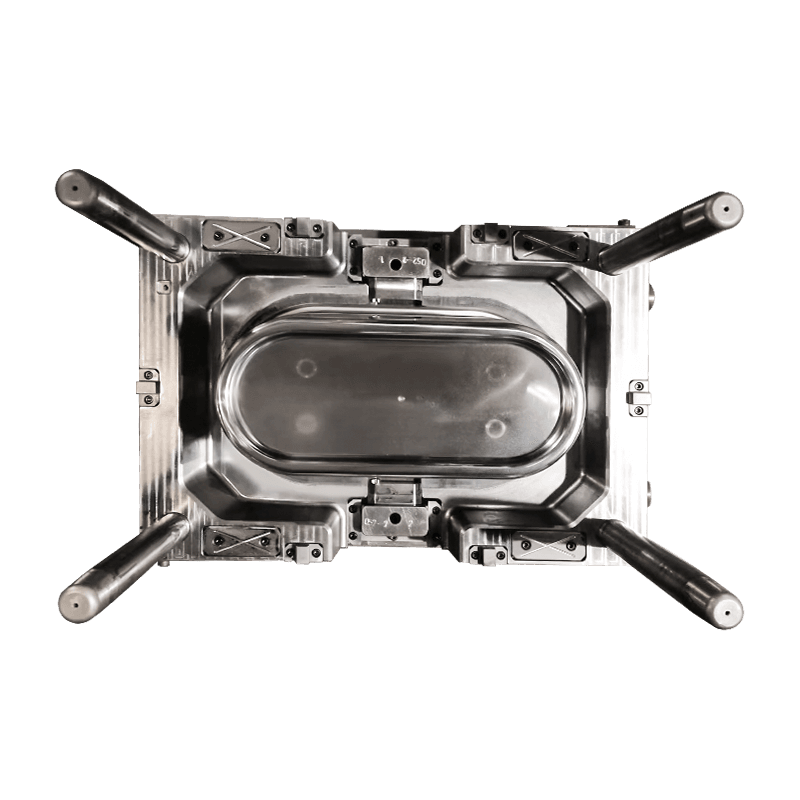

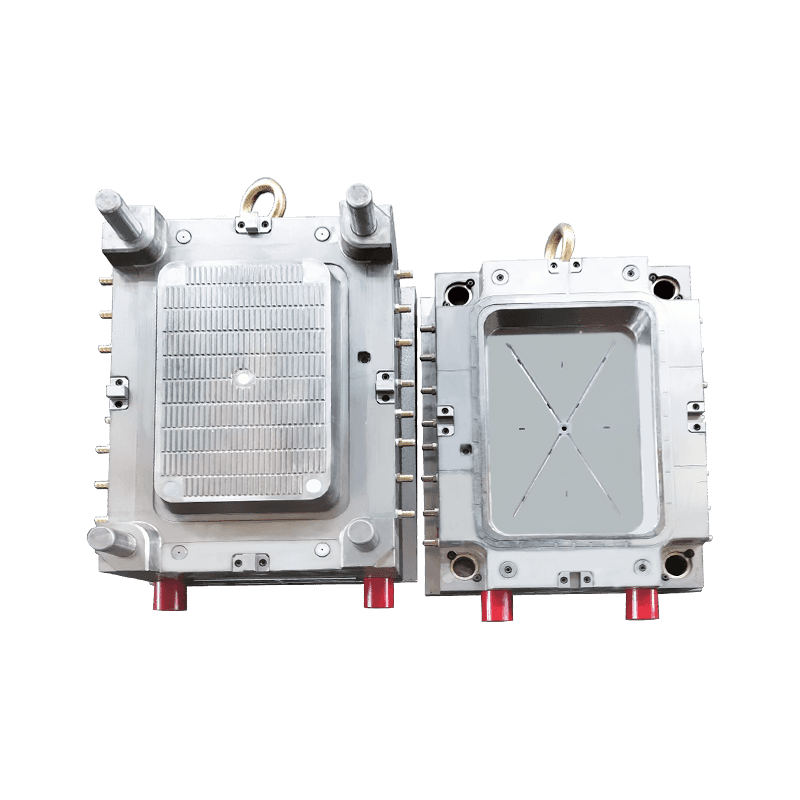

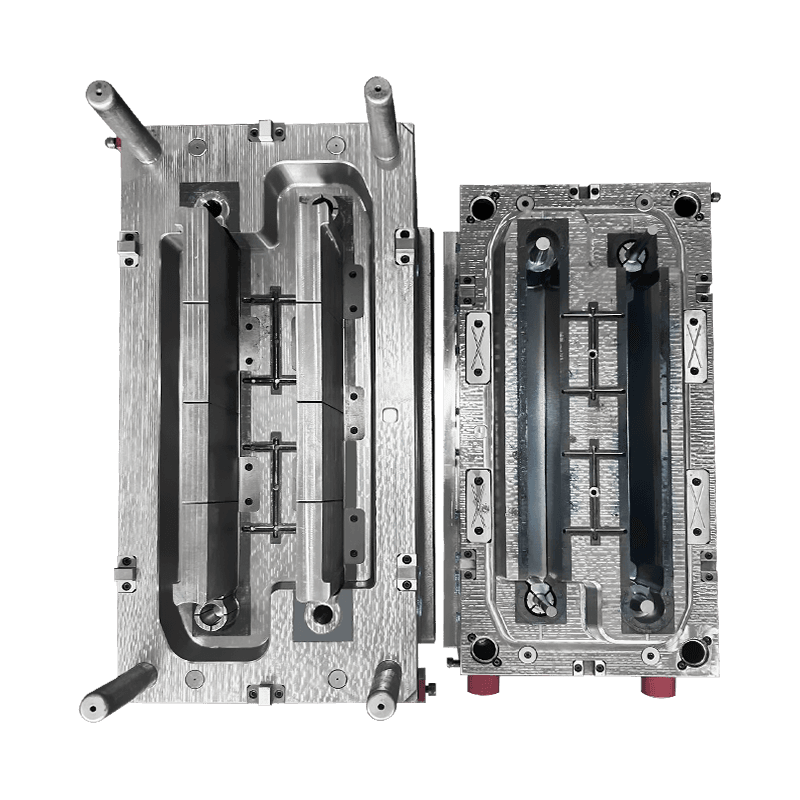

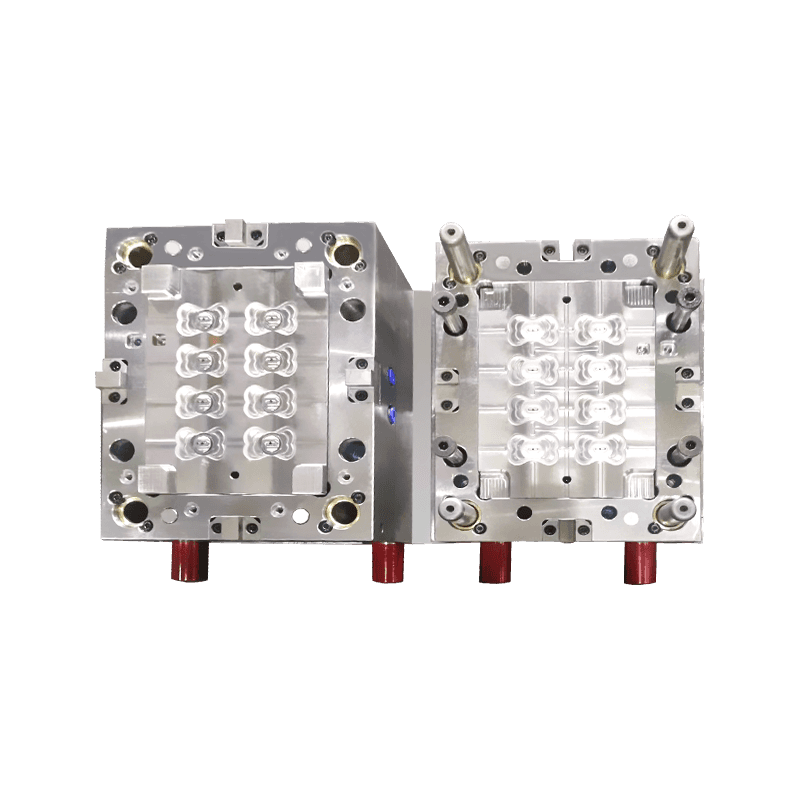

The process of creating large plant pots through plastic injection molding is a sophisticated blend of technology and craftsmanship. The molds used in this process are designed with precision and engineered to withstand the rigors of high-pressure injection molding.

Materials and Properties:

The materials used in these molds are carefully selected for their durability, heat resistance, and dimensional stability. Typically, steel alloys are chosen due to their strength and ability to maintain shape under high temperatures. The properties of these materials are crucial for ensuring the molds can produce pots with consistent quality and detail.

Design and Precision:

The design of a large plant pot plastic injection molding mold is a complex task that requires a deep understanding of both the material being molded and the end product's intended use. Precision is key, as even the slightest imperfection can affect the final product's quality. The mold must be designed to allow for easy ejection of the molded pot and to material waste.

Production Process:

The injection molding process involves melting plastic and injecting it into the mold under high pressure. The mold is then cooled, allowing the plastic to solidify into the desired shape. This process is repeated multiple times, with each cycle producing a new plant pot. The efficiency of this process is heavily reliant on the quality and design of the mold.

Maintenance and Durability:

Proper maintenance of the mold is essential to ensure a long service life. This includes regular cleaning to remove any residue and periodic inspections for wear and tear. The durability of the mold is a testament to the materials and craftsmanship that go into its creation.

Plastic Flowerpot Mould Manufacturers

The manufacturers of plastic flowerpot mould play a pivotal role in the gardening industry. They are the artisans who translate the needs of gardeners and the demands of the market into functional and aesthetically pleasing products.

Innovation and Design:

Plastic flowerpot mould manufacturers are at the forefront of innovation, constantly exploring new designs and materials to improve the functionality and appearance of plant pots. They must consider factors such as drainage, aeration, and the pot's ability to support plant growth while also ensuring the pots are visually appealing.

Customization and Flexibility:

One of the strengths of plastic flowerpot mould manufacturers is their ability to offer customization. Whether it's a unique shape, size, or design, these manufacturers can create mould that meets specific customer requirements. This flexibility allows for a diverse range of plant pots to cater to different gardening styles and preferences.

Quality Control and Assurance:

Ensuring the quality of the mould is a top priority for manufacturers. Rigorous quality control processes are in place to check for any defects or inconsistencies in the mould. This commitment to quality ensures that the end product meets the high standards expected by gardeners and retailers alike.

Sustainability and Environmental Considerations:

In today's environmentally conscious world, plastic flowerpot mould manufacturers are also looking at ways to make their products more sustainable. This includes using recycled materials, reducing waste in the production process, and designing pots that are easy to recycle at the end of their life cycle.

Market Trends and Adaptability:

Staying ahead in the market requires a keen eye on trends and the ability to adapt quickly. Manufacturers must be aware of the latest gardening trends and be ready to produce mould that reflects these changes. This adaptability is crucial for maintaining a competitive edge in the market.

English

English 中文简体

中文简体 русский

русский

Contact Us